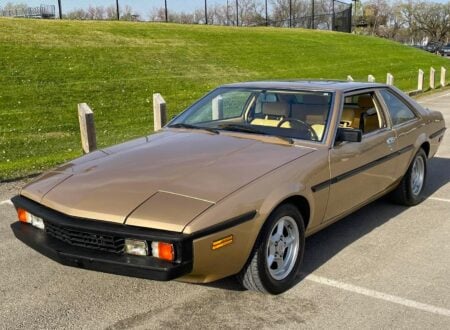

Project Utah – The Jaguar Mk I

The story of the Jaguar Mark II (also known as the Jaguar MK2) begins with Jaguar’s “Project Utah” which gave birth to the Jaguar 2.4 liter and 3.4 liter Mark I. These models then went on to father the Jaguar Mark II and then the Daimler 2.5 V8 which was, in my humble opinion at least, the cream of the crop even though it didn’t have a Jaguar name badge on it nor a pouncing cat leaping forward on its hood.

Work began on the new Jaguar “Project Utah” in May 1952 and it was to herald a number of firsts for the company, the most challenging was to be the decision to move from Jaguar’s old chassis and body construction to unitary construction. Unitary construction (unibody construction) was by the early 1950’s thought to be the future of passenger car construction and indeed that would turn out to be the case for volume production cars worldwide.

In order to create their new car Jaguar’s engineers Bill Thornton and Cyril Crouch worked with Britain’s Pressed Steel company to put the styling sketches done by Jaguar’s founder and boss Sir William Lyons into actual blueprints. The other member of the team was an engineer named Bob Knight who was specifically tasked with the job of dealing with the unibody’s inherent problems of noise, vibration and harshness (abbreviated as “NVH”).

Noise, vibration and harshness were a characteristic of a unibody construction that presented new technical challenges. The old fashioned methods of insulating a passenger car body from these problems with a chassis and separate body typically involved using rubber or other insulating materials in the attachment of the body to the chassis to dampen out unwanted vibrations and noise. These tried and familiar methods could not be used in a unibody and so other means had to be figured out. Bob Knight would go on to become one of the foremost experts in this field. The resulting body of the Jaguar Mark I was one of Sir William Lyons and his team’s great successes and was a tribute to the Jaguar sales motto of “Grace, Space, Pace”.

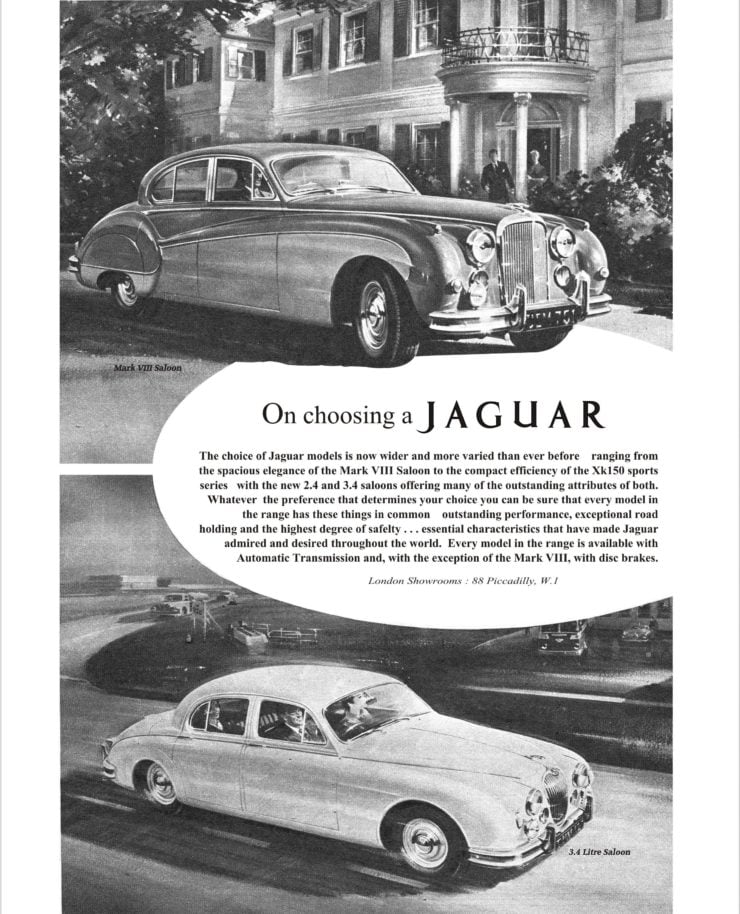

Jaguar was already manufacturing the XK120 sports car, and large luxury saloon the Mark VII, but management realized that their model range was comprised of expensive cars with big engines and that if there was an economic downturn that they would need to be producing a smaller and more economical model in order to survive.

This had been understood from Jaguar’s pre-war beginnings when they were called SS Cars. They had models using the Standard Motors Company engines of 1.5 liters capacity in their more affordable models in addition to the Standard Motors 2.5 liter and 3.5 liter engines installed in their more expensive offerings.

During the war years Sir William Lyons and his engineering team quietly got to work on the creation of a new engine to power the Jaguar cars of the post war era once the pesky Nazis had been defeated and Britain was once again restored to being the “Land of Hope and Glory” and lots of people would be able to buy a nice new and glorious Jaguar.

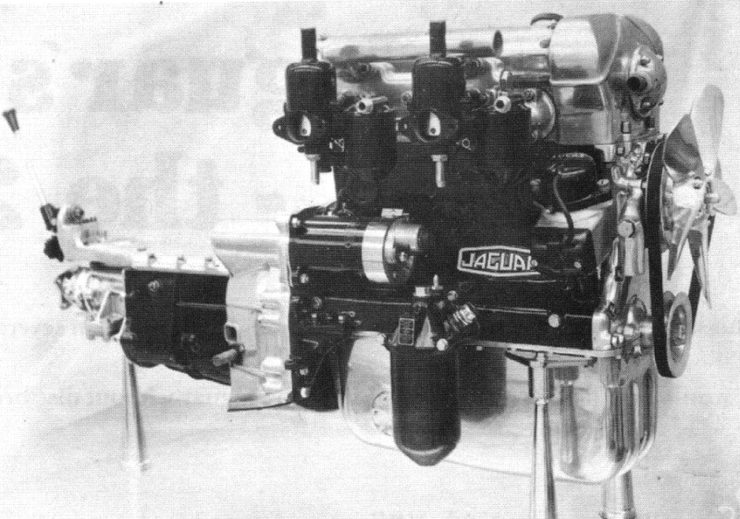

To this end the initial new engine design work focused on a DOHC, inline-6 cylinder engine of 3.4 liters capacity. This new engine was also able to be reduced in capacity by shortening its stroke to make it into a 2.4 liter engine. But what of a 1.5 liter? Jaguar’s engineers had also worked on cutting down the six cylinder to make it into a four cylinder of around 2.0 liters capacity, which would have given them a range of three engines whose capacities corresponded to the pre-war engine choices but which would have been far more advanced than the old Standard Motors units.

In the 1952 design and planning for the new Jaguar saloon both the 2.4 liter six cylinder and 2 liter (1,970cc) four cylinder engine options were worked on as alternatives for the production car. It would be the fact that the new car was going to weigh around 2,800lb that would prove to be the deciding factor in the decision to abandon the four cylinder engine. The four cylinder just had no hope of enabling the car to attain one of its design objectives: it had to be able to make 100 mph. As it turned out even the 2.4 liter six cylinder was borderline in achieving “the ton” in regular production cars.

The other factor in abandoning the four cylinder engine was that it was seen to be too “down-market” and therefore something that would cheapen the prestige of the Jaguar brand. An inline-4 cylinder engine does not have the sweet balance of a straight six and cannot offer the same sort of smoothness unless it is fitted with a balancing system such as that created by Frederick W. Lancaster back in 1904.

There was much tweaking by Jaguar’s engine boffins to get the 2.4 liter refined into the production version. The final six cylinder used a slightly shorter engine block than the 3.4 liter original engine and it had a bore of 83mm and stroke of 76.5mm to create an engine with a capacity of 2,483cc. This new engine version was to be fitted with twin Solex carburetors rather than Jaguar’s traditional preference for the products of Skinners Union (i.e. “SU”). This engine produced a healthy 112bhp @ 5,750rpm with torque of 140lb/ft at a leisurely 2,000rpm.

This sophisticated engine was mated to a British Moss four speed manual gearbox which, in stick-in-the-mud British style only had synchromesh on the top three gears but did provide the option of a Laycock de Normanville electric overdrive for quick and economical open road travel.

The front suspension was mounted on a separate sub-frame, one of the methods used to reduce the NVH in a unibody car, and was designed by William Heynes. It used double wishbones and coil springs with telescopic shock absorbers and an anti-roll bar at the front. For the rear a simplified version of that used on the Jaguar D-Type sports car was used with the live axle being supported by inverted semi-elliptic leaf springs which were cantilevered into the rear of the unibody in rubber insulated bushes.

These springs served the role of trailing arms and then lateral support for the live axle was provided using a Panhard Rod. The inverted leaf springs served to transfer the load of the live axle forward into the unibody shell. The Salisbury live rear axle gave the Mark I car a narrower rear track than the front and this was in all probability only done because it was the only suitable off-the-shelf Salisbury axle that was a close enough fit.

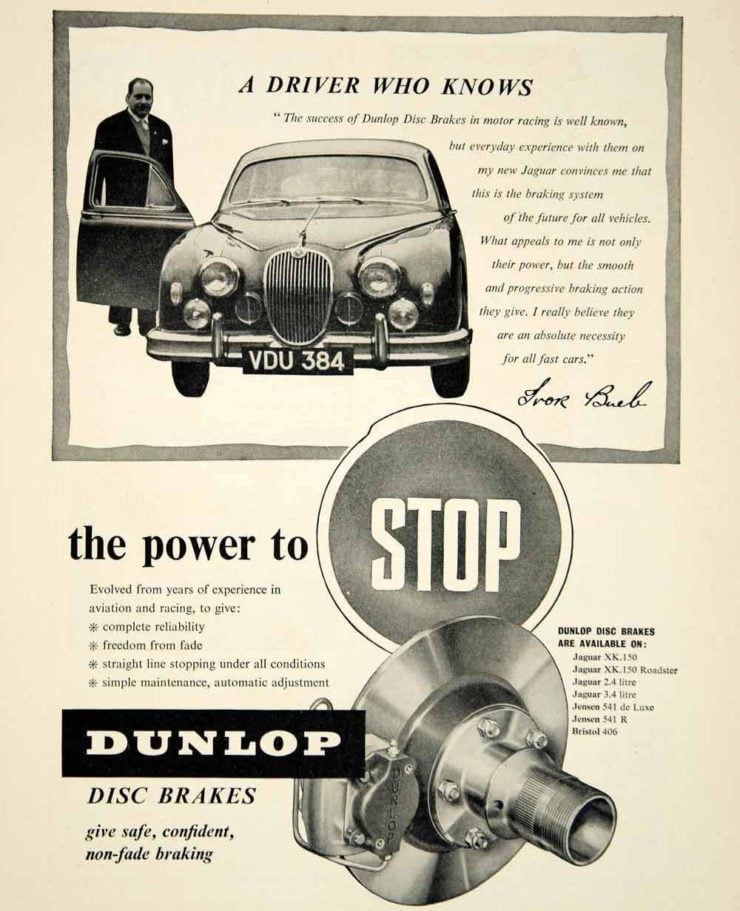

The brakes of the Jaguar Mark I were Girling drums all around of 11.125″ (283mm) diameter. At the end of 1957 the then new disc brakes on all four wheels would be offered as an option.

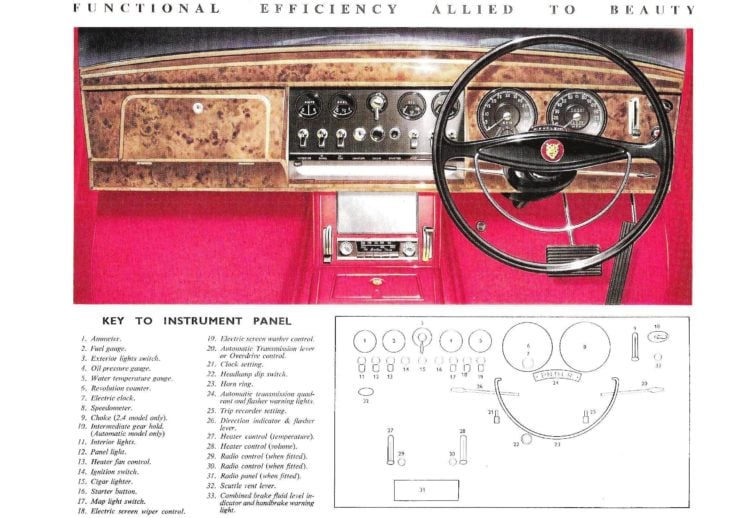

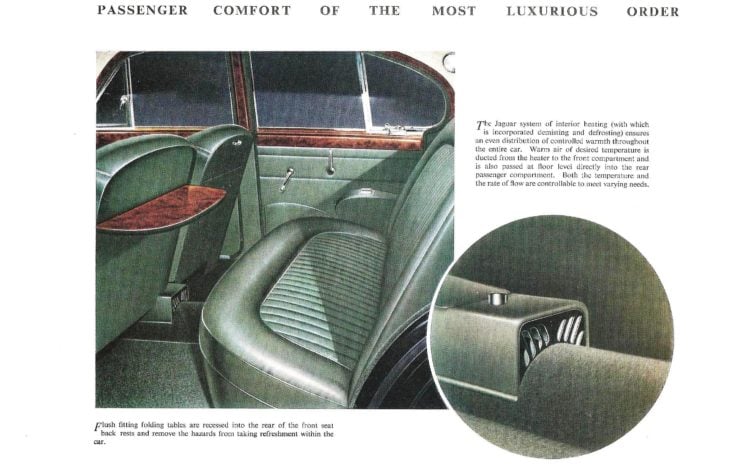

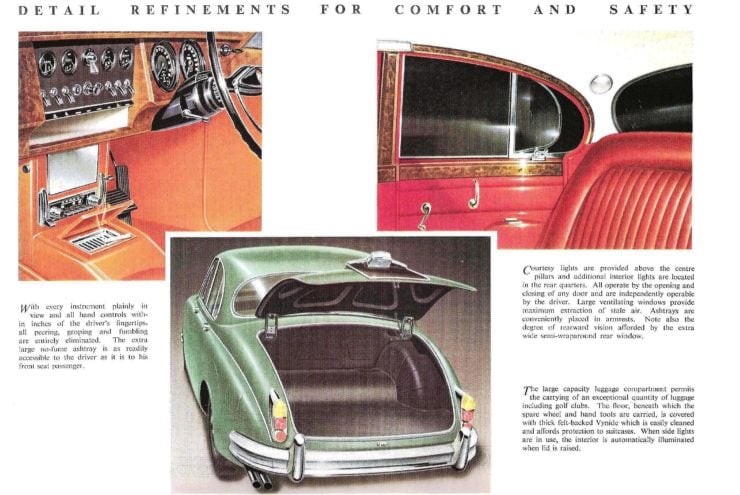

The interior of the Jaguar Mark I was a sumptuous blending of walnut veneer and leather, complimented by a carpeted floor. The interior of a car can make or break a sale and Sir William Lyons was very adept at giving his cars an aura of luxurious quality. The dashboard of the Mark I was laid out to make adaptation between right and left hand drive car production as easy as possible but it was, and still is, one of the most ergonomic designs created in the period.

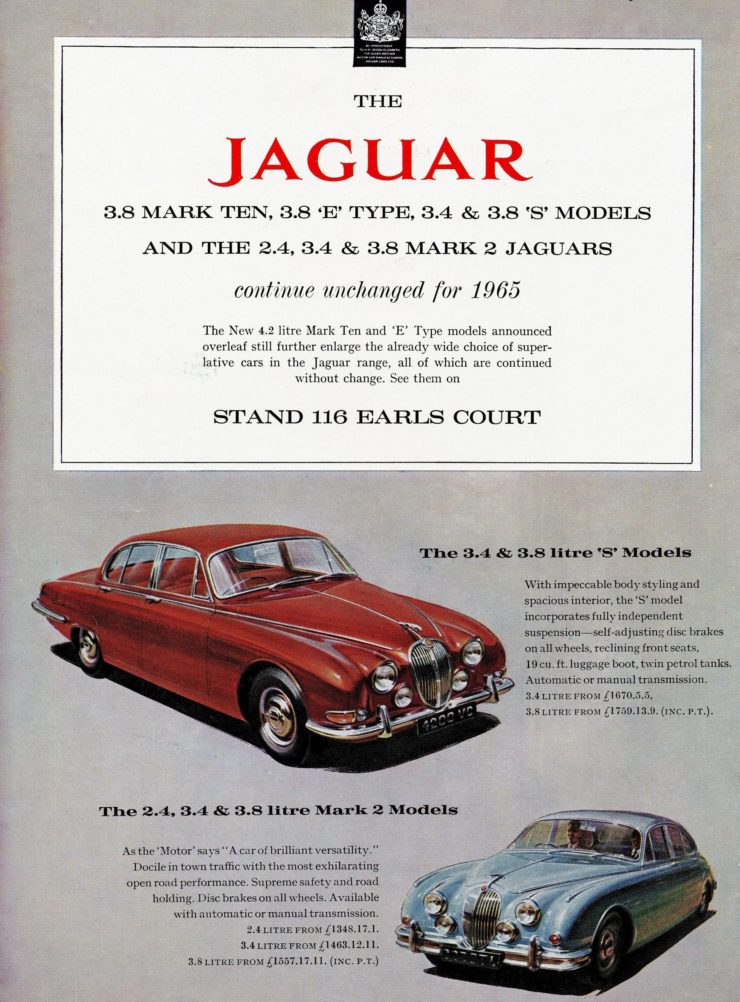

The Jaguar 2.4 liter Mark 1 made its public debut at the London Earls Court Motor Show of October 1955 and was offered in either standard or “Special Equipment” versions. The standard did not have a heater/demister or tachometer and for a rather modest £29 extra one got not only the tachometer and heater/demister but also twin fog lamps, a cigar lighter (which back then was used for lighting cigars and cigarettes and not for charging your iPhone), windscreen washers, courtesy switches for interior lights, and a folding center armrest for back seat passengers. In short you got a lot extra for your additional £29.

Production of the 2.4 liter Jaguar Mark I got going in earnest in 1956 with 8,029 cars produced that year. Given that the 2.4 liter Mark 1 was borderline as to whether or not it could do 100mph Jaguar were careful to ensure that any car sent to the motoring press for review was specially selected and prepared so it would. The car loaned to Britain’s “Motor” magazine was a Special Equipment model fitted with the Laycock de Normanville electric overdrive and on test it delivered a standing to 60mph time of 14.4 seconds and a top speed of 101.5mph. Fuel economy was 24.4 miles to the Imperial gallon.

For 1956 Jaguar offered three optional tuning kits for the 2.4 liter Mark 1 which provided power outputs of 119bhp, 131bhp, and 150bhp. This was to be an interim measure however as Jaguar already intended to install the full size 3.4 liter engine in the car. It would appear that the decision to do this had not been made when the design for the 2.4 liter Mark I was finalized and so some significant modifications had to be made to shoehorn the longer 3.4 liter engine with its bigger cooling system into the car: among the changes required was a larger grill to draw in cooling air for the larger radiator and also modification of the front wings.

The 3.4 liter version of the car went on sale in February 1957 with the new engine fitted with twin SU carburetors delivering 210bhp @ 5,500rpm with torque of 216lb/ft @ 3,000rpm. It was initially only fitted with drum brakes like its smaller engined sibling but negative reviews prompted the factory to fit disc brakes as standard equipment in January 1959 where previously they had been an optional extra. A manual transmission car with electric overdrive loaned to Britain’s “Autocar” magazine delivered a standing to 60mph time of 9.1 seconds and a top speed of 120mph.

The Mark 1 Jaguar was taken out of production in June 1959 to make way for its improved replacement, the Mark 2.

The Jaguar Mark 2 – The Gentleman’s Express

The Jaguar Mark II was an upgrading of the Mark I and went into production later in 1959. The relatively narrow rear track that had been subject to criticism despite the fact that it did not significantly affect the car’s handling was widened with the fitting of a new live axle.

The front and rear suspension designs remained unchanged other than the necessary changes to the geometry required. Four wheel disc brakes were fitted as standard equipment and a new addition was the provision of a limited slip differential for the 3.8 liter engine model. Options included the Laycock de Normanville electric overdrive for manual cars, automatic transmission and power steering.

Above the car’s waistline the changes were subtle but significant. Sir William Lyons and his team increased the glass area by 18% through widening of the windscreen and dramatically enlarging the rear window. Similarly the side windows were enlarged with the rear quarter windows forming the Jaguar “D” shape that would become a familiar feature on other Jaguar cars.

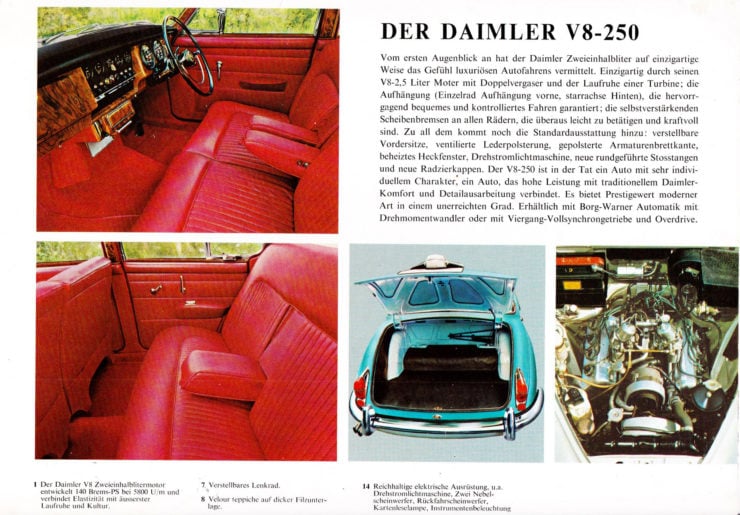

The interior of the car kept true to the design of the original Mark I but was upgraded, retaining the overwhelming impression of being surrounded by walnut wood veneer while being ensconced in sumptuous leather. If you weren’t completely captivated by the outside appearance of the car you were pretty much guaranteed to fall in love with the interior, I know I did, and just to make everyone’s joy complete the heater was ducted through to the rear of the passenger compartment to provide luxurious comfort for all.

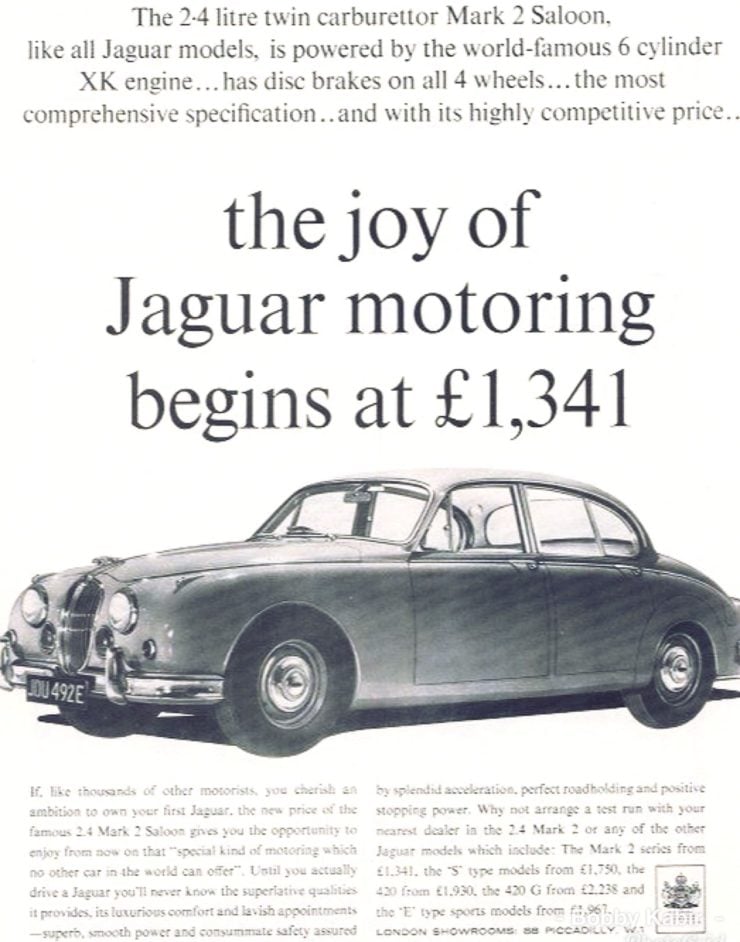

The Jaguar Mark II was made with three engine options, the 2.4 liter and 3.4 liter carried over from the Mark I and a new 3.8 liter. The 2.4 liter (2,483cc/152 cu. in.) version with twin Solex carburetors delivered 120bhp, the 3.4 liter (2,483cc/152 cu. in.) with twin SU HD6 carburetors provided 210bhp, while the 3.8 liter (3,781cc/231 cu. in.) also fitted with twin SU HD6 carburetors put 220bhp beneath the driver’s right foot. The Jaguar Mark II shared its 3.4 liter 210bhp engine with the 3.4 liter Jaguar XK150 SE and its 3.8 liter 220bhp engine with the 3.8 liter XK150 SE.

The Jaguar Mark II remained in production until September 1967 when the 3.8 liter version was phased out and the 2.4 liter and 3.4 liter models were re-badged the Jaguar 240 and 340. The 240 and 340 were run-out models intended to use up the remaining inventory of Mark II parts and to fill the gap while the world anxiously awaited the new Jaguar XJ6, which would make its debut in September 1968.

The Jaguar 240 and 340 were downgraded in terms of quality and fittings. The upholstery was changed to Ambla imitation leather while the fog lamps were replaced with vents, with fog lamps being an optional extra for the British market. Production of the Jaguar 240 and 340 ended in 1969.

Edward Turner’s All British V8 and the Daimler 250

British engineer and executive Edward Turner worked at Triumph and he had been responsible for such famous engines as the Ariel Square Four, and the Triumph parallel twin. Triumph was owned by the Birmingham Small Arms company nowadays better known for the BSA motorcycles it produced rather than for the Martini-Henry rifles they produced during the Victorian Era, and the brilliant sporting rifles they made during the 1950’s and 1960’s.

BSA owned the Daimler car company, Daimler having been a preferred car for Britain’s Royal Family for decades making it a prestige name, historically on a par with Rolls Royce. In 1956 Edward Turner was appointed as Managing Director and was asked to create a V8 engine to power a new range of Daimler luxury cars. Turner, his design engineer Jack Wickes, and Dr. J. N. H. Tait (who had previously worked with Donald Healey) started out examining the parts list for a Cadillac V8 and worked on incorporating design elements from the cylinder heads Turner had created for Triumph motorcycles which incorporated hemispherical combustion chambers.

The final design was for V8 engines in two capacities but with very similar dimensions and weight. The smaller being a 2.5 liter (2,548cc/155 cu. in.) producing 140bhp @ 5,800rpm with torque of 150lb/ft @ 3,600rpm intended for medium size cars or perhaps a sports car, and the larger a 4.5 liter (4,561cc/278 cu. in.) producing 220bhp @ 5,500rpm with torque of 283lb/ft @ 3,200rpm for large cars and limousines fit for a king or queen to ride in. These engines were 90° V8’s with two valves per cylinder actuated by push-rods from a chain driven camshaft located centrally high in the “V” of the engine.

The cylinder block was made of cast chrome-iron while the cylinder heads were of high tensile sand cast aluminum alloy. Pistons were of aluminum alloy while the connecting rods were of steel. The crankshaft was supported by five main bearings and the engine breathed through twin semi-downdraft SU carburetors.

These engines were put into production by Daimler with the 2.5 liter being fitted into their Daimler 250 sports car while the 4.5 liter was used in Daimler Major Majestic luxury saloons.

On 26th May 1960 Jaguar bought Daimler Cars from BSA not because they wanted to incorporate Daimler cars into the Jaguar product line, but because they wanted to use the substantial Daimler factory works to expand their capacity to make more Jaguars. Thus it was that Jaguar acquired what is arguably the greatest British V8 engine ever created, with all its potential attractiveness to American car customers who were and still are V8 engine aficionados.

Jaguar wanted to make Jaguars, but Daimler dealers wanted to sell Daimlers. A compromise was arrived at in which a Daimler, fitted with the Daimler 2.5 liter V8 engine, would be created using the Jaguar Mark II. Daimler were not given much to work with: there was an abandoned Jaguar Mark I sitting unused which was given to the Daimler boffins to see if they could squeeze a Daimler 2.5 liter V8 into it. They succeeded, and the resulting car was so good it was decided to build a Daimler badged “Jaguar” Mark II with the Edward Turner V8 in it.

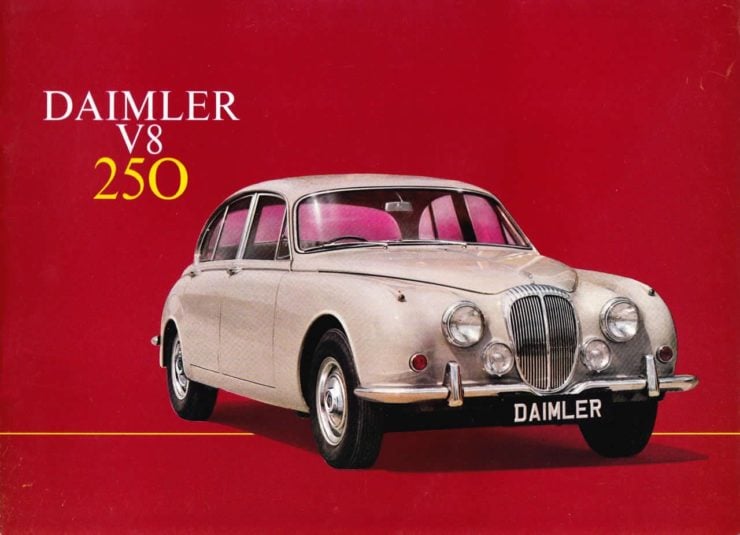

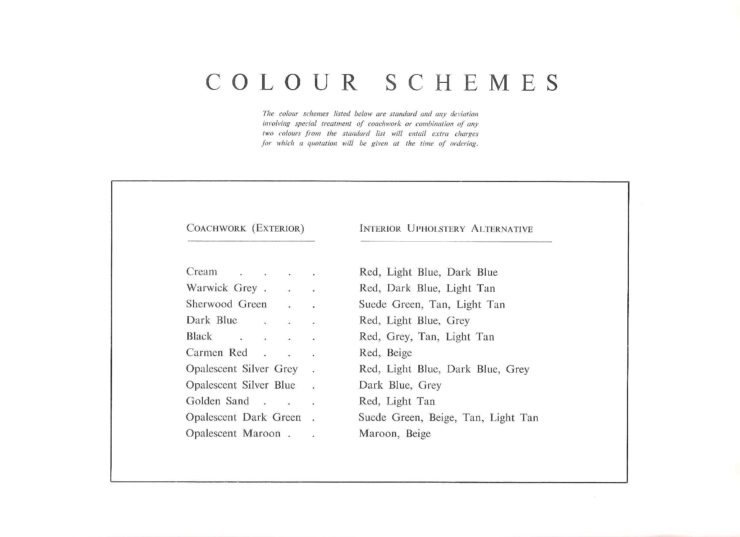

The car was christened the Daimler 2.5 V8 and produced from 1962-1967, and it would later go on to be renamed the Daimler 250 produced from 1967-1969. The Edward Turner V8 was shorter than the inline six cylinder Jaguar XK engine which gave the Daimler a better front to rear weight distribution and consequently better handling. It was first offered with an automatic transmission but received the option of a manual with electric overdrive in February 1967 shortly after production had started. Many consider this to be the ultimate “Jaguar” Mark II, a sentiment I happen to agree with. I can’t help but wonder what a “Jaguar” XJ6 fitted with the option of either the 2.5 liter or 4.5 liter Daimler V8’s would have been like. Its the sort of project Britain’s custom workshop Vicarage would do a marvelous job on.

The “Bank Robbers’ Car”

There can be no doubt that Sir William Lyons did not intend to create a motor car that would become the getaway car of choice for Britain’s underworld crime gangs, but it did. It was similar to what happened in Germany when the BMW “Neue Klasse” cars proved to be so quick that the communist terrorist group the “Baader-Meinhoff” gang tended to choose them over most other cars to the extent that the letters “BMW” came to be facetiously said to stand for “Baader-Meinhoff Wagen”.

The British did not tend towards communist terrorism back in the 1960’s but bank robbery was considered to be a viable business project for some in the criminal underworld and the Jaguar Mark I and Mark II saloons were found to be pretty much perfect for bank robberies because you could get a few gang members with illegally acquired guns and masks in the passenger compartment and there was room in the boot for a satisfying quantity of crisp freshly acquired bank notes or gold bullion. Not only that but the stolen Jag was near guaranteed to be much faster than the typical Wolseley police cars of the day. Thus it was that the Jaguar Mark I and Mark II were so adept at providing “Grace, space and pace” that they also became known as “Bank robbers’ cars”.

Conclusion

The Jaguar Mark II and its predecessor the Mark I were the first of the unibody “modern” Jaguar cars and they became the car that most people in the 1950’s and 1960’s would have recognized as a “Jag”. They pioneered the way for Jaguar’s ultimate replacement for them, the graceful Jaguar XJ6. The Jaguar Marks I and II were much different to the XJ6 however in that they looked like luxury sports cars with four doors and performed like sports cars: a feature that made them popular with car enthusiasts and bank robbers alike.

These are cars that enthusiasts and collectors are often willing to spend significant amounts of money doing a full restoration on and there are companies such as Vicarage who specialize in doing such restoration work to produce a car that is without doubt far better than it originally was when it emerged from Jaguar’s factory.

As for me I think the Daimler 2.5 liter was the cream of the crop and no doubt there is room for much enjoyable debate on the merits of which version of the Mark II was the greatest. I have a penchant for V8’s: how about you?

Picture Credits: Jaguar.