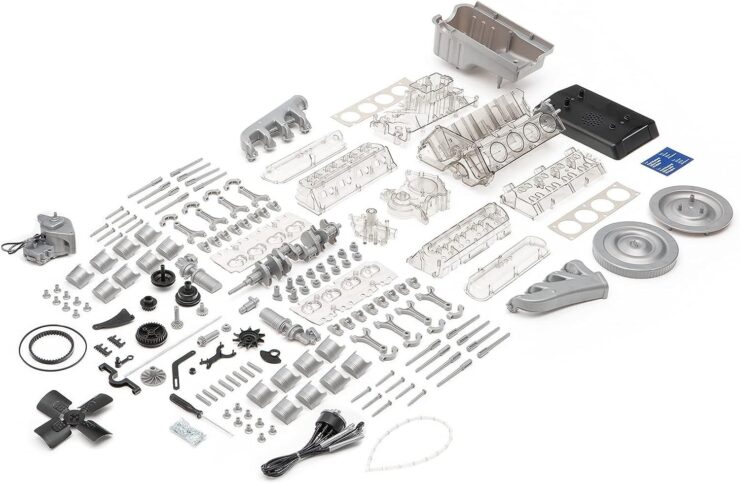

This is a transparent Ford Mustang K-code V8 that is made up of over 200 individual parts, it can be assembled in 3-4 hours, and thanks to the included electric motor, can be turned on so you can see the pistons, conrods, crank, and valves all working just like the original.

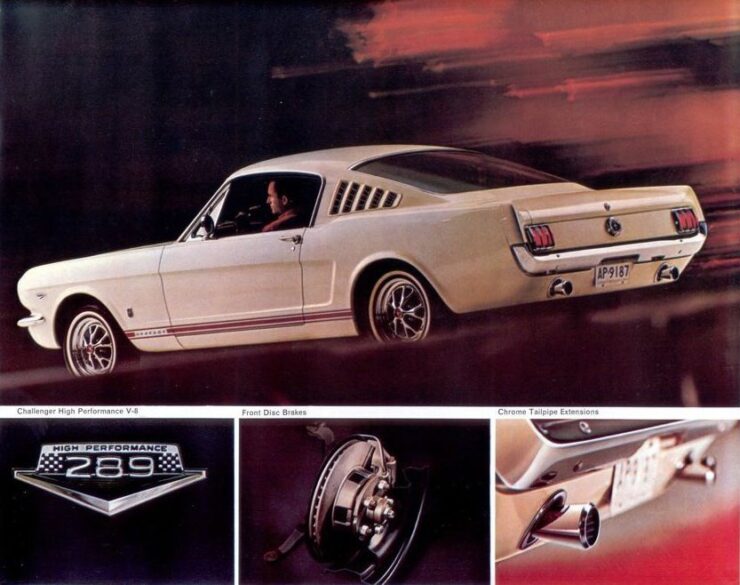

The “K-code” engine was the highest-performance engine you could opt for in the original Ford Mustang. Also known as the K-code Hi-Po V8, this engine was built with Ford 289 V8 blocks that had been specially inspected to ensure they could withstand the rigors of competition use.

The K-code engine was built at Ford’s Cleveland Engine Plant No. 1 in Brooke Park, Ohio. Once the perfect block had been found, the engine would be built by hand using a slew of high-performance parts, and once completed it would be capable of 271 bhp at 6,000 rpm – vastly more than the base C-code’s 200 bhp from the same 289 block and 4.7 liter displacement.

Each K-code V8 was built with the aforementioned inspected 289 block, to this a special crankshaft was added – these were cast using higher levels of nickel and magnesium than the standard 289 crank, then inspected to ensure they were perfect. Additionally, this crank had a small “hatchet” shaped counterweight to the front of the crankshaft.

The connecting rods were cast using the original molds but they were made for a larger 3/8-inch retaining bolt, and they had less material machined from the sides as part of the production process. They also had a heavy-duty rod cap for the larger rod nut that was used.

The pistons were cast from high-strength aluminum to better withstand the higher compression ratio used, they also had four valve reliefs. The K-code also used a solid-lifter camshaft, mechanical lifters, uprated valve springs, hardened retainers, and a stronger camshaft thrust plate.

The heads were similar to the standard production units, but they made use of screw-in rocker studs and cast-in valve spring seats to better withstand sustained high-RPM operation. The K-code engines built for Mustang use by Ford had cast-iron, dual-plane intake manifolds with an Autolite 4100 4V carburetor, but the modified versions built by Carroll Shelby’s team for use in the Shelby Cobra and the Shelby GT350.

The Transparent Mustang K-Code 289 V8 Model Shown Here

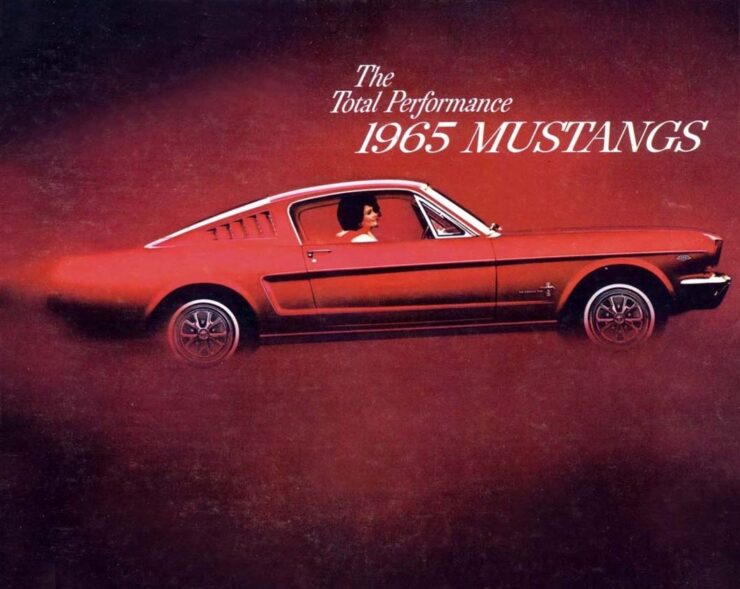

The engine model you see here is the 1965 version of the Ford Mustang K-code, though of course it wasn’t made by Ford in Brooke Park, Ohio, it was made by German model company Franzis. This engine is 1:3rd scale model designed with a number of transparent parts so you can see the internals at work.

The model consists of over 200 individual pieces, once assembled and the batteries are fitted it has both a sound module to recreate the sound of the original V8, and an electric motor to rotate the crankshaft – moving the connecting rods, pistons, pushrods, rocker arms, and valves just like the original.

These models are a great way to teach kids (or adults) how gasoline internal combination engines actually work. This model retails for $197.97 from Franzis via their international Amazon store and each comes with a 100 page booklet, that includes details and illustrations guiding you through the history of the Ford Mustang.

Images courtesy of Franzis + Ford