Above Image: A Lotus 7 battling with a Porsche 356 Speedster in 1984. Image courtesy of the San Francisco Region SCCA.

In the Beginning: Motorsport in the Mud

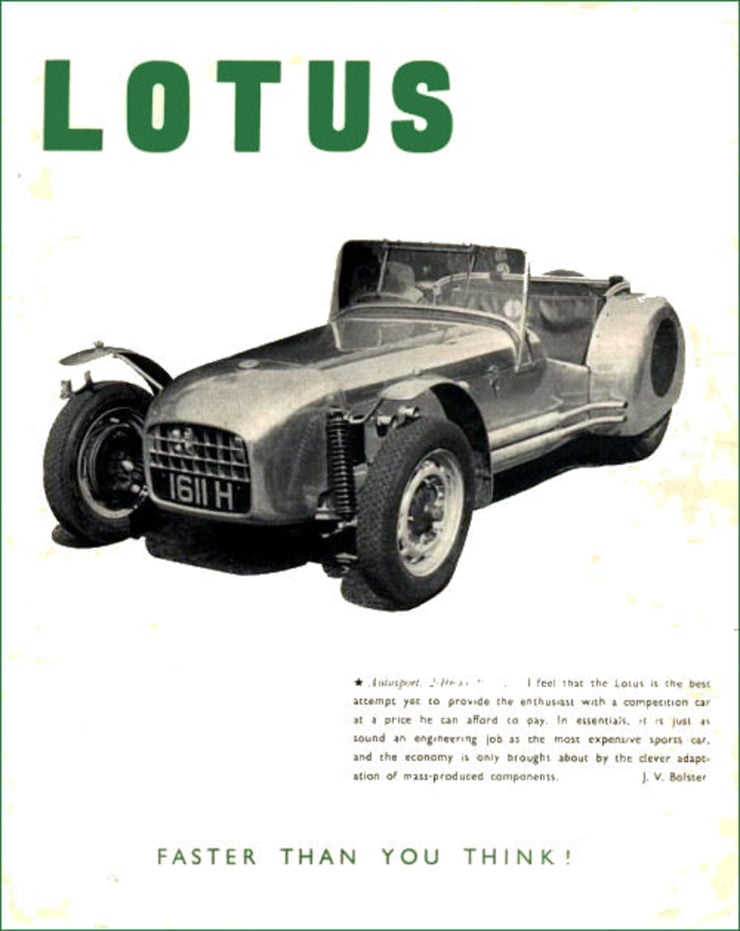

Lotus Cars, and thus the Lotus 7, can be said to have begun in the mud. This muddy beginning was in the British motorsport of “trials” which evolved to include muddy hillclimb sections in which the competitor had to maintain forward motion of their car or be disqualified.

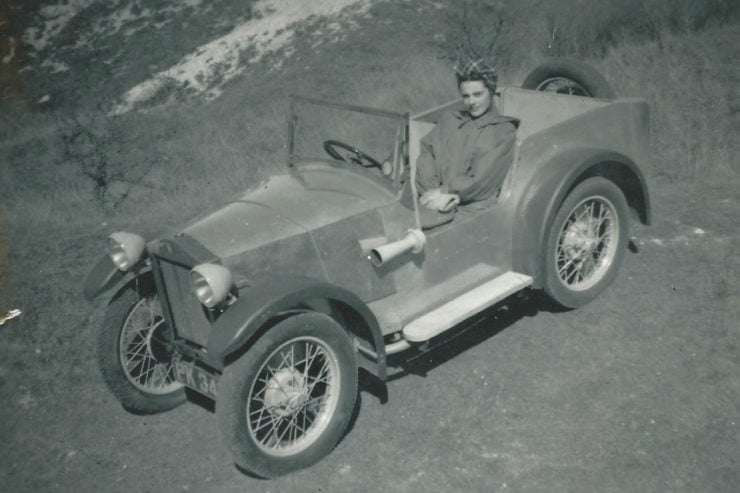

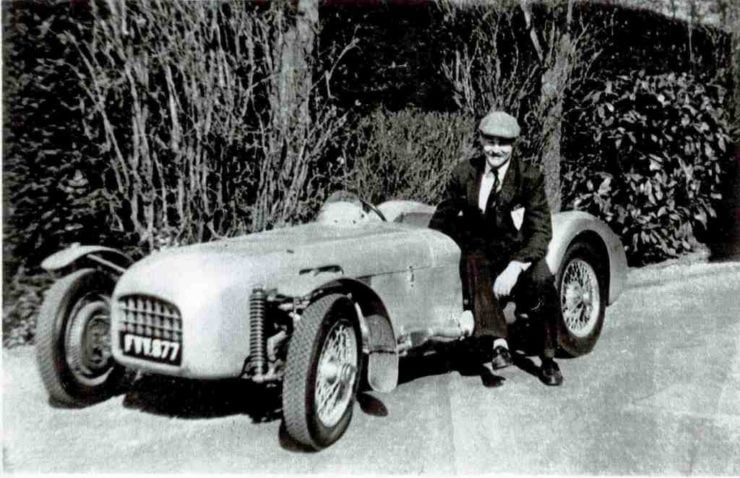

Colin Chapman, the founder of Lotus, made his humble entry into car making in 1948 by taking an old Austin 7 and rebuilding it with a custom body of his own design into a trials car. That “Lotus Mark 1” first trials car was the genesis from which Lotus Cars would ultimately be born.

Above Image: The Lotus Mark 1

Colin Chapman had built and competed in his first car while he was still studying engineering at University College London and it may have been the distraction that stalled his getting his engineering degree as he had to re-sit his mathematics paper in 1949 to finally graduate. But he was a young man with a vision at that time not knowing what the future held for him. He had a plan, and the determination to see that plan through to fruition.

Above Image: The Lotus Mark 1

From Muddy Hill to Race Track

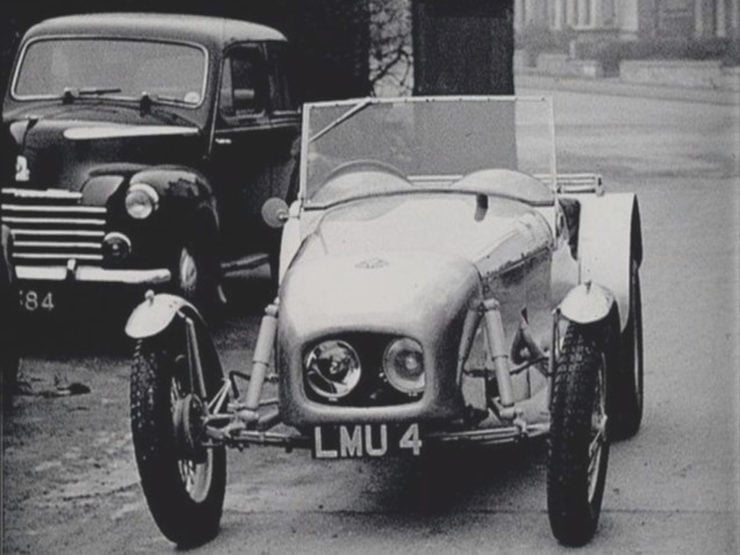

The Austin 7 was the first stepping stone and Chapman then set about creating a Lotus Mark II which would be a great improvement over the Mark 1 despite the fact that it too was based on an Austin 7. The Mark II featured a chassis which Chapman improved by boxing the chassis members and replacing the original cross members with more structurally sound tubular braces.

Working to create a car that would be within the rules for trials events and also for use in the “Clubman” class for track racing Chapman pulled out the old Austin 7 engine and in its place went an engine and gearbox from a Ford 8, which would subsequently be upgraded to one from a Ford 10. Wider tyres were desirable so they were acquired and fitted to Ford steel rims.

Above Image: The Lotus Mark II with Colin Chapman at the wheel.

This car was successful but Colin had his eyes on track racing, and in order for him to become a sports car maker he needed to establish some “street cred” on the race track. Chapman entered his home built “Lotus Mark II” into an eight car race at Britain’s prestigious Silverstone race track on June 3, 1950, and managed to win the event ahead of a Type 37 Bugatti. Having his “parts bin special” home built racing car win against a Bugatti was a great encouragement and no doubt was good publicity also.

Above Image: The Lotus Mark III

The Lotus Mark III followed on from this. Made for the “750 Motor Club” track racing competition these were also based on the Austin 7 but with chassis modifications much like the Mark II and engine tweaks that served to establish buyer demand for Chapman’s “Lotus” cars although he was at that time still working full time for British Aluminium and making cars in his spare time as a hobby.

Above Image: The Lotus Mark IV

The Lotus Mark IV came next: still based on the Austin 7 but with an 1172 cc Ford four cylinder side-valve engine. This car was made for racing driver Mike Lawson who had previously had much success in a Mark II and in the improved Mark IV he enjoyed so much more success that it became viable for Colin Chapman to establish Lotus Engineering in partnership with Michael Allen in an old stable in North London’s Hornsey district 1952.

From the Lotus VI the Lotus 7 is Born

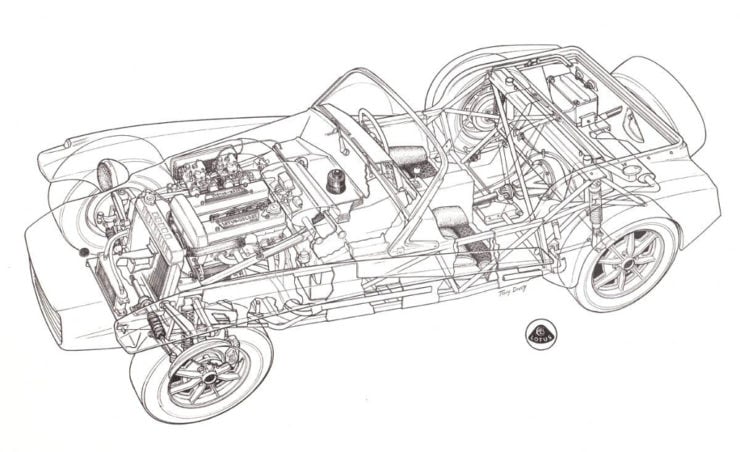

With the move into an actual production premises, Chapman and Lawson developed two strands of sports racing cars; the Lotus VI kit car which would go on to father the Lotus 7, and the pure bred sports/racing cars beginning with the Lotus Mark VIII, Mark IX, Mark X, and the gorgeous Lotus Eleven. These cars shared on thing in common, none of them were based on the Austin 7 but instead all were constructed around spaceframe chassis created by Chapman.

The Lotus VI was one of Colin Chapman’s first opportunities to design a chassis and car from scratch and he put the things he’d learned while studying engineering at University College London to good use. The complete frame of the Lotus VI weighed just 55 lb with the original prototype being constructed in accordance with Chapman’s design by the Progress Chassis Company who would subsequently make the production chassis. This featherweight chassis was then clothed with the most minimalist bodywork of beaten aluminium made by panel-beaters Williams and Prichard who were also then given the task of making the production bodywork.

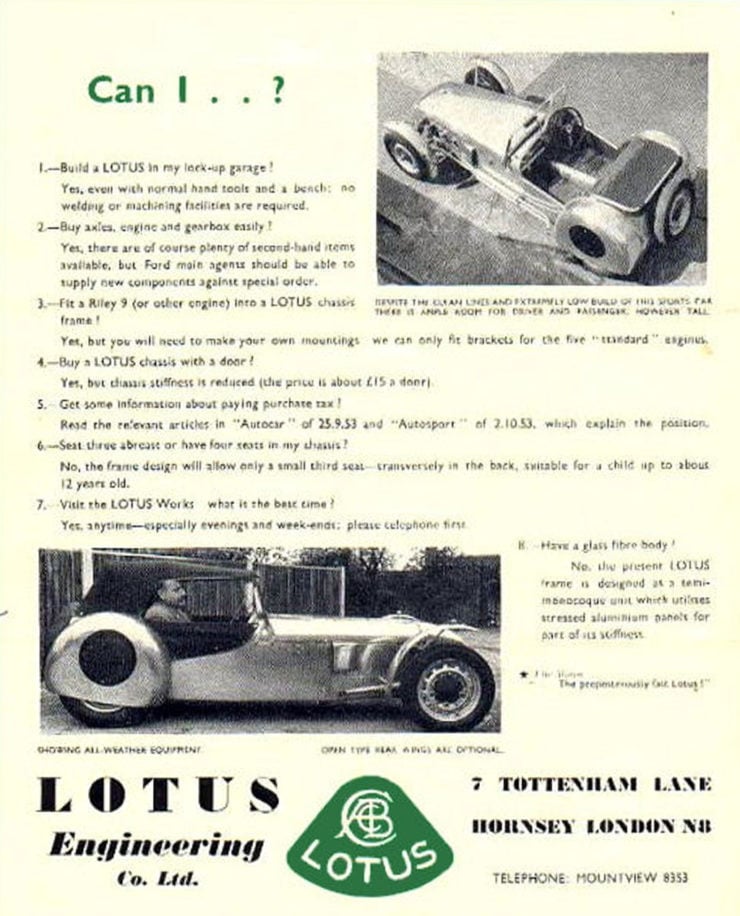

Selling a car as a kit meant that Lotus could sell them free of Britain’s sales tax, which applied to complete cars. The snag with that is that the kit car was not allowed to be sold with assembly instructions, or it would be taxed. Applying a bit of reverse logic Colin Chapman sold his kit cars with “disassembly” instructions, so the new owner could simply follow the instructions in reverse to construct their car.

The Lotus VI was made between 1952-1957 and sold as a very complete kit customized for the owner to install a variety of possible engines and transmissions. The optional standard engines for which mountings were supplied began with the 40 bhp 1,172 cc side-valve engine as used in the pre-war Ford 10. The Ford 10 was in production between 1932-1937 and in post-war Britain these were one of the cheap and available second-hand engines for an enthusiast to rebuild and performance tune, and the three speed gearbox could also be used.

The second engine choice was for the more up-market MG TF 1,466 cc OHV four cylinder which produced 63 hp @ 5,000 rpm in standard trim. The MG TF was in production between 1953-1955 so these were new engines and could be had with a four speed gearbox.

The third engine choice was the four cylinder OHV 1,508 cc producing 47 bhp of the Ford Consul made between 1951-1962. This engine could be had with the standard three speed manual gearbox with synchromesh on the top two gears and a hydraulic clutch.

For those with more money and a desire to get the best the Lotus VI kit came with mountings for a Coventry Climax engine. These were the Harry Mundy designed “Feather Weight” FWA, and later FWA Mark II. These engines were aluminium with overhead camshaft and of up to 1.5 litres capacity. They made a name for themselves in Formula 2, and then in Formula 1 famously installed in the Cooper Climax.

The Lotus VI was designed for the enthusiast on a budget as a car that could be driven to the track, raced, and then driven home. It was intended to provide for the hobby amateur racer but Colin Chapman had much bigger ambition than that, he saw the Lotus VI as a stepping stone, and he wanted to shed the kit car image of Lotus and move on to much more ambitious projects.

In 1953 Colin Chapman and aerodynamics expert Frank Costin began work on the first of the pure bred sports racing cars, also built on a spaceframe chassis. This group of cars would begin with the Lotus Mark VIII followed by the Mark IX and Mark X, all as development versions, bringing them to the Lotus Eleven which was built between 1956-1958

Although Chapman wanted to move away from the kit cars he could see that he needed the income from them to continue towards his vision of becoming a maker of top end sports and GT cars, and to be a maker of cars that would become icons of motor racing including in Formula 1 and in such prestigious events as the 24 Hours Le Mans. So by 1957 he created an improved successor to the successful Mark VI, the Lotus 7. This was to become a car that would prove to be so timeless in its conceptualization that it is still in production to this present day, no less than sixty three years later.

The Lotus 7

The Five “De Dion Sevens”

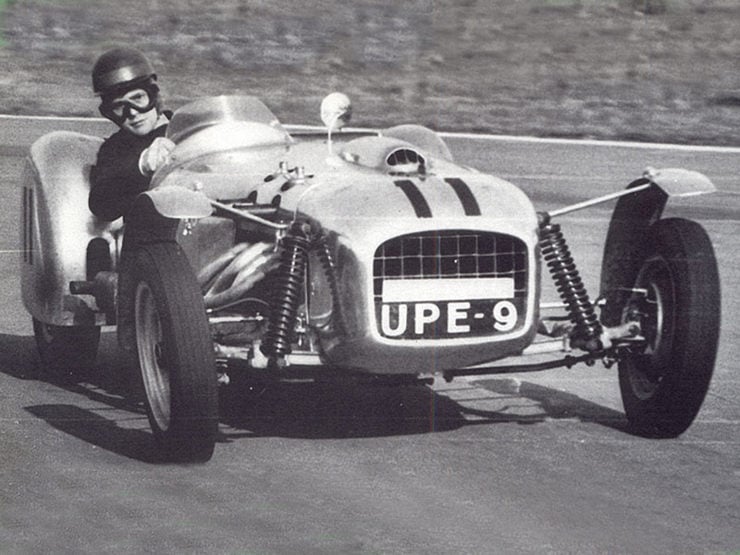

Colin Chapman had reserved the number seven Lotus designation specifically for a car that would be the successor of the highly successful Mark VI. But with the pressures of keeping up with Lotus other projects in 1956-1957 the idea of creating such a car was very much in the background and was in some doubt as to whether it would actually ever happen. One of the events that pushed the project from “do it later maybe” status to “get started” status was a keen Lotus competitor named Edward Lewis who had been very successful in his Mark VI and in a Mark IX but felt that he was getting a bit past his “use by” date for serious track racing and wanted a simple purpose built car for hillclimb events.

The car that Lotus constructed for him was dubbed the “Edward Lewis Special” and it was based on the tried and true Mark VI spaceframe chassis but with Lotus Mark IX running gear with a De Dion rear suspension. The engine was an 1,100 cc Coventry Climax with impressive performance credentials and the car was completed with an aluminium body of Lewis’s own design which was made by Williams and Pritchard, who made the Mark VI bodywork.

Edward Lewis began competing in his new car in September 1956 and notched up several successes, which captured Colin Chapman’s attention. The event that swung Colin Chapman’s thinking to act on creating a car to use the reserved Lotus 7 number occurred in early 1957 when he and his wife Hazel were having dinner with friend Mac MacIntosh and the discussion turned to Lotus car model line-up. It was Colin’s wife Hazel who suggested that Lotus should make a simple and inexpensive car to replace the VI, noting that the beautiful Lotus Eleven was expensive to buy and expensive to repair. Colin Chapman saw the wisdom in his wife’s suggestion and he and Mac MacIntosh got stuck into drawing the new car, based on the Lotus Eleven.

The first prototype was really a “Le Mans” specification Lotus Eleven with bodywork in the style of the Lotus VI. It was complete within a week and Colin Chapman wanted to get it into testing to see just how it would perform. To this end he did a bit of horse trading with Edward Lewis and swapped his Edward Lewis Special for the prototype Lotus 7. The prototype Lotus 7 was fitted with a Coventry Climax SOHC 1,098 cc engine with a four branch exhaust, Austin A30 gearbox, De Dion rear suspension with an axle providing a 4.5:1 final drive, knock on wire wheels shod with Dunlop racing tyres, and disc brakes. Lewis racked up successes on his first outing with the car at the Brighton Speed Trials held on 7th September 1957.

Lotus made four more of these special prototypes, three fitted with the Coventry Climax 1,098 cc Coventry Climax FWA engine as was fitted to Lewis’s car, and one with a 1,460 cc Coventry Climax FWB engine.

Colin Chapman had prototype cars out on test with owners and they proved the viability of the concept. However, being based on the Lotus Eleven these prototypes were more expensive to build than wanted for the production Lotus 7. The design would have to be rationalized to turn it into the sort of inexpensive sports/competition car that was envisaged.

The Lotus 7 Series 1 (1957-1960)

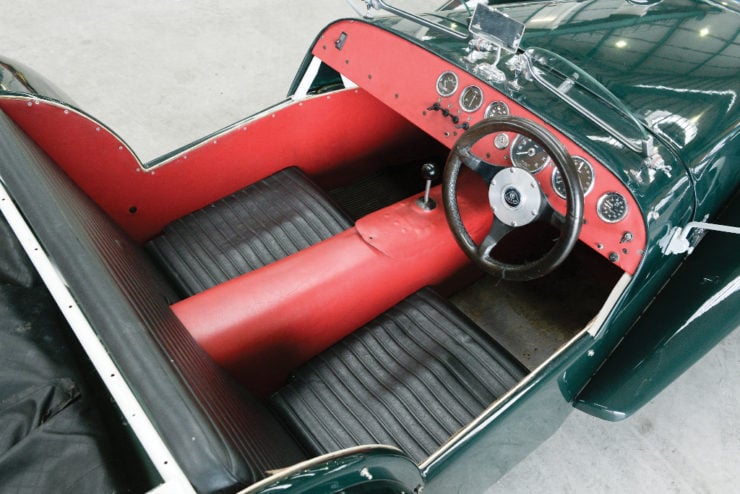

Although based on the Lotus Eleven the production Lotus 7 was made with an eye on keeping it inexpensive, easy to construct and maintain, and exciting to drive. Its styling evoked just a hint of the 1950’s BRM Formula 1 cars as had the Mark VI before it. With its spaceframe chassis and stressed-skin aluminium bodywork the Lotus 7 was a delightfully austere example of Colin Chapman’s design philosophy “Simplify, then add lightness”.

Chapman’s Lotus 7, like his Formula 1 cars, did not depend on simply adding power because he understood that the speed of a car did not depend on power alone, but on its power to weight ratio: and the lighter the car the better its handling could be made to be. Hence he also said “Adding power makes you faster on the straights; subtracting weight makes you faster everywhere”.

In the first production model of the Lotus 7 Colin Chapman’s desire to subtract weight led to him deciding that for the front suspension he would use a conventional lower “A” arm but instead of having an upper “A” arm he could save weight by using an anti-roll bar as the forward link of the upper suspension arm. This saved some weight but also meant that the front suspension was semi-independent and not fully-independent.

The front suspension was supported by coil springs over telescopic shock absorbers. The steering of the early Series 1 cars was by a Burman worm and nut steering box but this was upgraded to a Morris Minor rack and pinion system. Wheels were 15″ and brakes were hydraulic twin leading shoe 8″ cast iron drums all around with a mechanical handbrake.

The rear suspension incorporated a Nash Metropolitan live-axle because keeping costs down was all important and the Lotus 7 was designed around using commonly available parts. That live axle was supported by twin trailing arms with a diagonal link, coil springs and telescopic shock absorbers. The weight of a Series 1 Seven was around 1,100 lb (500 kg) and its fuel tank capacity was seven Imperial Gallons giving it a range of about 200 miles depending on how light-footed or lead-footed the driver was.

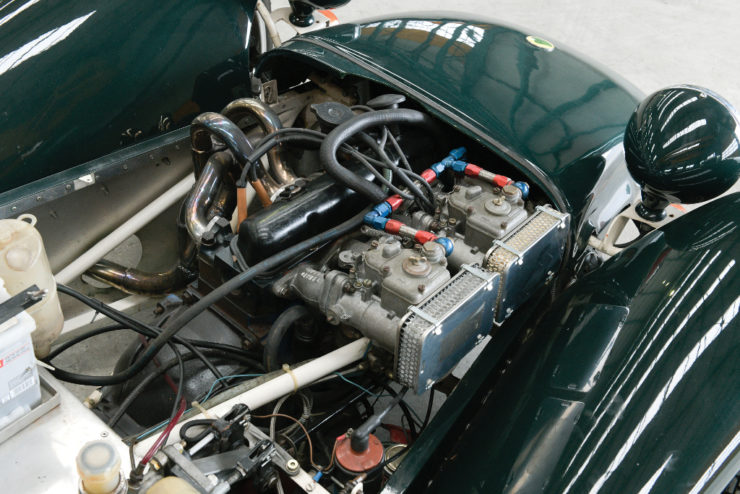

For the Series 1F the engine was to be the Ford 100E 1,172 cc 40 hp side-valve inline four cylinder engine with an 8.5:1 compression ratio and breathing through a single Solex carburettor: the same engine that had been used for the base model of the Lotus VI. This meant that the car was suitable for 750 Club racing.

In addition to this standard version of the 100E engine a tuned sports version was also available. This engine was fitted with twin SU HS2 carburettors, a modified cylinder head with a higher compression ratio and stronger valve springs, and a four branch exhaust. This engine produced 48 hp. The 100E engines were fitted with the Ford three speed manual gearbox and close ratios were an optional extra.

Lotus wanted to export the Seven to the United States but the market demands there were very different to the British domestic market. Just four Series 1F cars were sent across the pond in 1958 and the Americans were completely unimpressed by the antiquated sidevalve Ford 100E engines. The solution to this problem was actually found by a Lotus customer who had installed a BMC A Series OHV inline four cylinder engine in his Seven.

This engine type was of 948 cc capacity and was used to power the Austin A35 and Morris Minor small cars which were very popular in Britain, being something like a British “Volkswagen”. This same engine type was also used as the heart of the Austin-Healey Sprite, familiar to Americans as the “Bug Eye” Sprite.

In its first iteration the car that would become the American model was installed with the BMC A engine of 948 cc fitted with a single SU H1 carburettor. This car was made in August 1959 and designated the 1A. It was fitted with the the aluminium alloy four speed manual gearbox as used in the Austin A30. This was not yet the “America” model however but a stepping stone towards it. It was still fitted with the bicycle type front fenders which would not be legal in some states in the US.

Work on the prototype “America” went on through the end of 1959 and into 1960. The new model was fitted with the 948 cc BMC A Series engine as used in the Austin-Healey Sprite which was fitted with twin 1⅛” SU carburettors and produced 43 hp @ 5,200 rpm and 52 lb/ft torque @ 3,300 rpm.

This new model featured fibreglass flared front wings which was in all likelihood a thing that Colin Chapman was not enamored with as such “clamshell wings” tended to act like fairy wings and were guaranteed to produce lift at speed. What one does not want is to have ones lightweight Lotus 7 lifting off the ground like the fairy Tinkerbell in Disney’s movie “Peter Pan” as the speedometer moves from “boring speed” to “eye popping excitement speed”.

The other engine that could be fitted to the Series 1 Seven was the Coventry Climax FWA SOHC inline four and this model became the 1C.

Performance of the Series 1 with the tuned Ford 100E 1,172 cc twin carburettor engine was quite impressive. When tested by Britain’s “The Motor” magazine the car delivered a standing to 60 mph time of just 6.2 seconds and was found to have a top speed of 80.4 mph. This lightweight little road rocket was also thrifty at the petrol pump with fuel consumption on test discovered to be no less than 31 miles to the Imperial Gallon. The Lotus 7 was quick, economical and fun, what more could one ask?

The Lotus 7 Series 2 (1960-1967)

Lotus were losing money on every Lotus 7 they sold and so they had to change the design of the Lotus 7 to make it cheaper to produce so they would make a profit on each car. 1960 was the crossover year when the Lotus 7 Series 1 was superseded by the Series 2, with the Super 7 following in 1961. The Series 2 was made with the aim of keeping the cost of the car low and so the spaceframe chassis was redesigned so it could be made with fewer tubes to reduce production costs. This model was given a new larger fuel tank held in place by steel straps and the battery was moved from the rear of the car to the front engine bay. Another cost cutting measure was the replacement of the hand shaped aluminium front nose cone with one made of fibreglass. The aluminium nose cones had required the specialized work of craftsmen trained on English Wheeling Machines, while the fibreglass ones could be fabricated with much less sophisticated methods. The Series 2 was made in the same versions as the Series 1, so there was a 2F, 2A, 2C, and America.

For the Series 2 the rear suspension was changed significantly with the Standard Triumph 4.5:1 rear axle mounted on an “A” frame that attached to the bottom of the differential with two trailing arms. This also served to help reduce production costs.

By 1960 13″ wheels and radial tyres were becoming increasingly popular with car makers and customers, and Lotus were experiencing difficulties purchasing the off-the-shelf parts needed to make their cars. With these two factors to contend with Lotus were able to source 13″ steel rims at a good price and in the required quantities from Standard Triumph and so the wheels were changed to 13×3½”J and the brakes of the Series 2 were also changed to 8″ drums from the Triumph Herald at the front and 7″ drums at the rear which came with the Standard 10 rear axle. The use of this combination kept the wheel stud fittings for front and rear matched.

The Series 2F retained the Ford 100E engine and three speed gearbox initially but in October 1961 this was upgraded to a Ford 105E inline OHV four cylinder engine of 997 cc capacity. This engine was fitted with twin SU HS2 carburettors and had an 8.9:1 compression ratio giving the engine 39 bhp @ 5,000 rpm.

This engine was optionally offered with Weber carburettors and a four branch exhaust. The 105E engine was mated to a Ford four speed manual gearbox with synchromesh on the top three gears. The rear axle ratio was 4.55:1.

1961 also saw the creation of the Lotus Super Seven. This car was fitted with a 1,340 cc inline OHV inline four cylinder engine from the Ford Consul Classic. This engine was not left standard however but tweaked up by performance tuning house Cosworth. Because human nature is “Always wanting more” more was indeed forthcoming and Lotus subsequently increased that engine size to 1,498cc, and then to 1,599cc.

The change to different Ford engines in part came about because the early Ford 1,340 cc engine only had three main bearings and it did not stand up to the special tuning done by Cosworth all that well. The later 1,498 cc and 1,599 cc engines had five main bearing crankshafts and could handle the extra power nicely.

From 1961 onwards the Lotus 7 could be had with disc brakes as these were being fitted to its donor production car, the Triumph Herald, from that year on and so this provision flowed on to the parts available to Lotus.

The Lotus 7 Series 3 (1968-1969)

The Lotus 7 Series 3 made its debut in August 1968. The first difference between it and its predecessor was the replacement of the Standard 10 rear axle, which was no longer able to be sourced, with a Ford Escort Mexico unit. In addition to being available this axle was also less prone to breakage and so was a great improvement. The new Ford rear axle was a bit wider and so required the rear wings to be made wider to accommodate it.

The second change was the change of engine to the OHV Ford 1,600 cc Crossflow engine that was used in the Ford Cortina passenger car: this was an engine that Lotus was familiar with as it was the heart of the Lotus Cortina GT. In the Lotus 7 Series 3 this engine was fitted with a Weber 32DFM carburettor and had a compression ratio of 9.0:1 giving it a power output of 85 bhp @ 5,500 rpm.

Although the Lotus 7 was made to be a budget priced sports car there were customers who wanted to invest money into their car and so in January 1969 Lotus introduced the Lotus 7 Twin Cam SS, fitted with the same Twin Cam engine as the more upmarket Lotus Elan. This engine developed 125 bhp and allowed the Lotus to get from standing to 60 mph in 6.1 seconds despite its being a couple of hundred pounds heavier than its predecessor. The Lotus 7 Twin Cam SS was a car with appeal to only a few enthusiasts however and only thirteen were sold: a factor that nowadays makes this model something of a “holy grail” for collectors and enthusiasts alike.

The Series 3 marked a shift to use of Ford components motivated by Lotus having developed a close working relationship with Ford at that point in their history, the creation of the Lotus Cortina being one of the more well known results of that cooperative relationship.

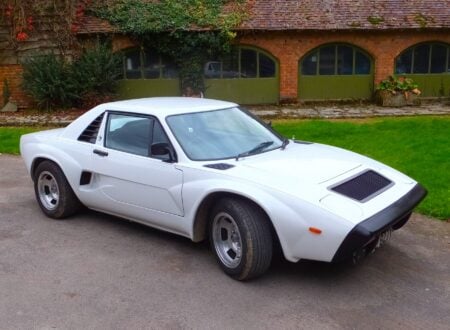

The Lotus 7 Series 4 (1970-August 1973)

The Series 4 was introduced in 1970 and it marked a move away from aluminium to fibreglass construction. Lotus more upmarket road cars such as the Lotus Elite and Elan had made extensive use of fibreglass with the Elite (1957-1963) using a fibreglass monocoque body while the Elan (1962-1973) used a steel backbone chassis and fibreglass bodywork.

The Series 4 was something of a departure from the Lotus 7’s that had gone before it: it was a bit bigger, and its steel spaceframe with stressed steel side panels and front section and fibreglass bodywork sharing the stress loads. It looked different, and it looked very trendy in a 1970’s sort of way and perhaps that was what Lotus were aiming for, to make the car more fashionable in the hope it might become a bit of a trendy icon for the “cool set”: sadly for Lotus it didn’t.

The square and boxy new look of the Series 4 might have been an effort to make the new Lotus 7 look 1970’s fashionable but the type of people who might be attracted to fashion were far too busy buying other trendy cars to even be aware that the Series 4 existed. The downside was that the customer base who were likely to purchase a Lotus 7 generally abhorred the look of the new Lotus 7 and so sales were disappointing: Lotus sold some, but they certainly did not fly out of the factory like little hotcakes. The Series 4 was fitted with the “Tinkerbell wings” front fenders of the US market models so of course it would have a bit of a Tinkerbell tendency to front end lift at high speed.

Technically the Series 4 marked an improvement over the previous models in the areas of driver and passenger comfort. It was more weatherproof, had more luggage space, and came with such niceties as a heater, windscreen washer, seat belts, and even black pile carpet to go with the ventilated vinyl seats and interior trim. So if you were planning on a winter trip up to Scotland or Canada then this was a Lotus 7 that would provide some protection against frostbite and hypothermia.

With its pigmented fibreglass bodywork the Series 4 was also durable and scratches could sometimes just be polished out. The standard engine fitted to this model was the Ford 2255E 1,600 cc OHV fitted with a Weber 32DFM twin choke carburettor, this engine also being used in the GT Cortina. In this state of tune with its 9.0:1 compression ratio the engine developed 84 bhp @ 5,500 rpm. This engine was mated to an all synchromesh Ford close ratio four speed manual gearbox and Ford live rear axle with a ratio of 3.77:1.

A small number of cars were made with a Ford 1,300 cc engine but this did not prove to be a popular option.

For those wanting to open up their wallets a bit wider to get a significant increase in power the Lotus Twin Cam engine of 1,558 cc was offered. This engine was fitted with twin Weber 40DCOE carburettors. This engine came in two stages of tune, the standard “Special Equipment” one delivering 115 bhp, or the Lotus-Holbay version pumping out 126 bhp.

In order to make this fun little speed machine lose velocity quickly it was fitted with hydraulic front 9″ Girling disc brakes which were obtained from the Triumph Spitfire, while at the rear were either 8½” or 9″ hydraulic drum brakes with a mechanical handbrake.

Wheels were either 13″x5½” pressed steel or alloy and the tyres were 165×13″ radials; either Dunlop SP Sport or Goodyear G800.

Steering remained by rack and pinion and the steering column was made collapsible for improved crash safety. The steering wheel was a sporty 13″ alloy unit with a nice non-slip PVC rim.

The front suspension was by upper and lower pressed steel “A” arms with coil springs, these being the same as used in the Lotus Europa. The rear suspension was by two Watts links with a transverse arm providing lateral support and coil springs with telescopic shock absorbers.

The electrical system was 12 volt negative earth and the battery was relocated back to the boot/trunk of the car where it had been mounted in the Series 1 cars previously. Fuel tank capacity was 7½ Imperial gallons.

The Series 4 would be the last of the Lotus built versions of the Lotus 7. By 1970 Colin Chapman had made the decision to finally unburden Lotus from its “kit car” origins and to transform the company into a maker of expensive high performance cars. By 1970 the design team at Lotus had created the concept for what would become the Lotus Esprit and in 1972 they had made arrangements with none less than Italian designer Giorgetto Giugiaro to design the body style.

At the 1972 Geneva Motor Show the new Lotus Esprit was shown beside the Maserati Boomerang on the Ital Design stand and Lotus was thus standing shoulder to shoulder with the best of Italian exotic cars. Thus it was that in 1973 Lotus shed the Lotus 7. It was to be picked up by Caterham, while the cars also continued in production being made by Steel Brothers in New Zealand and Lotus Argentina SA.

Steel Brothers had an arrangement with Lotus to assemble the Lotus 7 and were able to progressively assemble and sell the 95 kits they had in stock. Steel Brothers were an established company with considerable resources, they had for example been the maker of the first New Zealand Toyota Corona passenger cars in 1967. Their stock of Lotus 7 kits lasted them until 1979.

Another company with a license to manufacture Lotus 7’s was Lotus Argentina SA. They made 51 cars between 1970-1975.

A Parting of the Ways: Enter Caterham

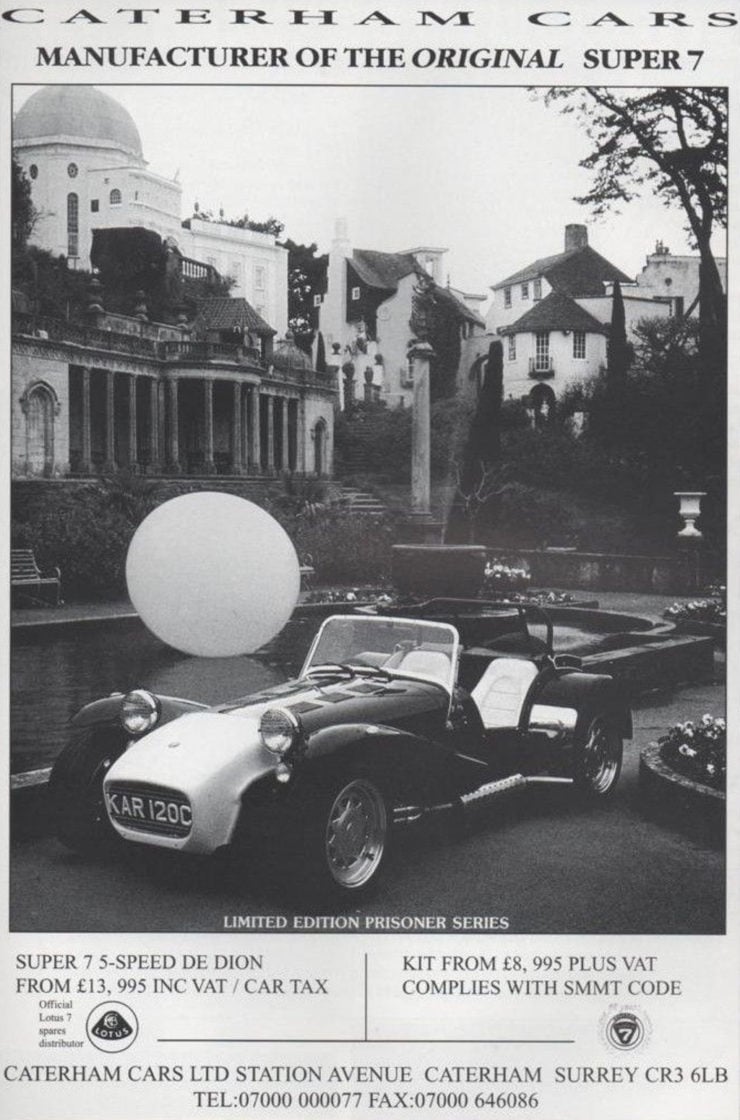

In 1973 Colin Chapman took the step to finally complete the metamorphosis of Lotus away from being an enthusiast’s kit car maker to enter the ethereal ranks of the exotic performance car makers. But one company could see that the Lotus 7 had a future, and that it was a car with extraordinary potential, potential that had not yet been fully exploited, and that company was Caterham Cars, based in the Town of Caterham in Surrey and under the leadership of Graham Nearn.

Caterham Cars had begun their business relationship with Lotus by becoming a Lotus dealer in the 1960’s and by 1973 they were the last remaining dealer selling and assembling Lotus 7’s in Britain. 1973 was a pivotal year because in that year Britain joined the European Economic Community which resulted in the ending of Purchase Tax, which had been levied on new fully assembled cars but not on kit cars, and its replacement with Value Added Tax, which was levied on cars whether they were sold complete or in kit form. So the tax saving that had caused Lotus to specialize in selling kit cars was abolished and in Colin Chapman’s mind this meant that the niche market for the Lotus 7 kits was at an end.

Caterham Cars however could see an opportunity to continue production of the Lotus 7 under their own name and they managed to purchase the rights to the Lotus 7 in 1973 so they could make the cars themselves under their own name. With the purchase agreement in force Caterham proceeded to progressively build the remaining Lotus 7 Series 4 kits they had in stock, and then they needed to make decisions as to how to proceed from there. Should they continue to simply make Lotus 7 Series 4 cars? Or should they do something more creative?

Amongst enthusiasts the Series 4 was best described as the most unloved of the Lotus 7’s, and the Series 3 was the one that people were most enthusiastic about. So for Caterham the decision was not particularly complicated: they decided to start building their own version of the Lotus 7 Series 3, initially using much the same sort of components that Lotus had. The suspension remained the same as the Lotus Series 3 and the Caterham cars retained the Ford rear live axle and suspension of their Lotus predecessors until the change was made to the Morris Ital axle in the early 1980’s.

In the mid-1980’s The team at Caterham decided to enhance the Caterham 7 by giving it a De Dion rear suspension, similar to the original Lotus “De Dion” Sevens. This was offered as an alternative to the older style live axle system up until 2002 when the live axle was phased out.

The Caterham 7’s did away with the “clamshell” front wings in favour of a return to the bicycle style mudguards that have much less tendency to cause lift at speed.

Caterham developed their own model range as the company moved into the twenty-first century ranging from sedate fun cars up to wild eyed speed addict machines. Engines of the early cars included the Lotus Twin Cam, Ford Crossflow, Cosworth BDR, and Vauxhall HPC including some “Evolution” versions from Swindon Race Engines. The Rover K-series began being fitted from 1991 in various sizes and states of tune, but the use of these engines had to cease when Rover/MG were sold to Chinese interests.

Caterham also experimented with motorcycle engines such as the Suzuki GSXR1300 as used in their Hayabusa, and the Honda CBR1100 which was installed in the Caterham Blackbird which could do a standing to 60 mph in 3.7 seconds and had a top speed of 143 mph.

In developing their model line-up Caterham decided that, great though the Series 3 Lotus 7 was, that there was a potential market for a larger version for people who just happened to be physically bigger that a mere 6′ tall, and to provide more interior space, and thus more comfort. To this end the SV (Special Vehicle) was developed. Interestingly despite having larger dimensions the weight of an SV was not greatly more than a standard S3, the difference typically being of the order of 25 kg, so you could have your space and high performance too.

Caterham settled on four main models; the Classic, Roadsport, Superlight and CSR. They also offered the “Academy”, which was sold as a “try motorsport” package which provided the buyer with a Caterham 7 Roadsport 125 (i.e. Sigma 125 bhp engine equipped), and training and competition events to participate in. These included three sprint and/or hillclimb events and four circuit races.

The Caterham 7 Classic

The Classic was the entry level Caterham 7. It was fitted with a Rover K-series 1.4 litre engine producing 105 bhp @ 6,000 rpm with 95 lb/ft of torque. This engine was mated to a five speed all synchromesh manual gearbox. The suspension was by double “A” arms with anti-roll bar at the front and a De Dion rear suspension using a lower “A” arm and upper radius arm.

Brakes were discs all around with a dual hydraulic circuit. Steering was by rack and pinion with 1.93 turns lock to lock. Wheels were alloy 6J x 14″ shod with Avon 185/60R14 Avon ZV3 tyres. The car weighed 1,201.5lb (545 kg) so the approximate power to weight ratio was 200 bhp per metric tonne.

The Caterham 7 Roadsport

Caterham described the Roadsport as being a “lightweight sportscar for all conditions. Combining high performance on the road with the practicality of weather protection, as well as the ability to excel on track that is inherent in all Sevens, this is the Caterham that will do it all.” So this was intended to be an all purpose sports car.

The Roadsport came with three engine options; a 1,600 Ford Sigma engine in either 125 bhp or 150 bhp states of tune, and the 2.0-litre Caterham Powertrain (CPT) Duratec engine delivering 175 bhp @ 7,000 rpm.

The car had a full windscreen and was fitted with a heater, cloth seats and carpet.

The Roadsport was available as either a standard Lotus 7 Series 3 size car or as a larger SV (Special Vehicle) size car suitable for taller drivers in the 6’6″ range.

The Caterham 7 Superlight

The Superlight was a track oriented car that was equipped with a 150 bhp 1.6 litre Sigma engine and six speed gearbox. The suspension was “wide track” for enhanced stability and the car was made in both standard and SV sizes.

This car weighed 1,157 lb (525 kg) giving it a power to weight ratio of 290 bhp per metric tonne and it would deliver a standing to 60 mph time of 4.7 seconds with a top speed of 125 mph.

The Caterham 7 Superlight R500

Described by Caterham Cars as delivering “Weapons Grade Driving Thrills” The R500 was fitted with a two litre Ford Duratec Caterham Powertrain (CPT) delivering 263 bhp @ 8,500 rpm and a power to weight ratio of 525 bhp per metric tonne because the car weighed just 1115.5 lb (506 kg) (or 516 kg if fitted with the optional sequential gearbox).

Given the power to weight ratio the Superlight R500 provides a standing to 60 mph time of 2.88 seconds, so the driver will be grateful it is provided with headrests, and the car had a top speed of 150 mph.

The R500 was fitted with 6J x 13” alloy rims at the front and 8J x 13” at the rear shod with Avon CR500 tyres.

The Caterham 7 CSR

For the person who wanted the ultimate Caterham 7 experience with Ford Duratec Cosworth engines the CSR models were created. These were made in three versions; the CSR200 fitted with a 2.3 litre Cosworth Duratec 200 bhp engine with five speed gearbox and made in the larger SV body, the CSR250 fitted with a 250 bhp version of that engine with a six speed gearbox and also made in an SV body, and the CSR Superlight with the 260 bhp engine in a diminutive Superlight car.

The wheels for the CSR series were Caterham Anthracite 15″x6.5″ front shod with 195/45R15 Avon CR500 Tyres, and 15″x9″ with 255/40R15 Avons at the rear.

The suspension of the CSR cars was also quite different. At the front the independent suspension system was inboard while at the rear the CSR featured an independent suspension.

The CSR200 delivered a standing to 60 mph time of 3.6 seconds and top speed of 140 mph, while the 260 bhp versions managed 3.1 second standing to 60 mph times and had top speeds of 155 mph.

The SV size CSR models weighed 1,267.7 lb (575 kg), while the Superlight weighed 1,212.5 lbs (550 kg). The CSR200 having a power to weight ratio of 347 bhp per metric tonne, the CSR250 452 bhp per metric tonne, and the Superlight 472 bhp per metric tonne.

Suffice to say that these cars were sufficiently exciting that those with heart conditions might need to emulate Carroll Shelby and keep a nitro-glycerine tablet under their tongue whilst driving or in the passenger seat.

The Caterham 21

Although the Caterham 21 is not called a “Seven” this car was instrumental in the development of the larger SV Caterham 7’s and the widetrack used in them.

The Caterham 21 was made in 1994 on a modified Caterham 7 spaceframe but featured a fully enclosed fibreglass body to make the car a stylish and lightweight conventional roadster. The 21 looked stylish and had the potential to be a brilliant road car. However Caterham found that the difficulties they encountered in creating the 21 led to customers being faced with long waiting times to get their car, and the early production cars were provided to customers as not quite finished prototypes. The result of these problems was the termination of the Caterham 21 project after only forty eight had been made.

Current Caterham Production

The best way to become familiar with the current Caterham model line-up is to visit their website and browse through their offerings.

You will find the current Caterham model offerings if you click here.

At the time of writing the Caterham 7 range begins with the Super Seven 1600, Seven 270, Seven 310, and Seven 420 which are all available as kits or as fully assembled cars. Moving up in the performance levels is the Seven 620 whIch is only available fully assembled.

In addition to their cars Caterham still offer the Academy Race Package and the more recent 420R Race Package.

Epilogue

The story of the “Seven” began in the mud of England’s green and pleasant land in the hopes and dreams of a university engineering student who aspired to becoming an exotic sports car builder. It was a journey that would lead Colin Chapman to take a series of bold but calculated risks as he progressed along in his journey from part time small scale production of competition cars for Trials enthusiasts and race track competitors to becoming the respected manufacturer of beautiful sports cars that Lotus has become.

Colin Chapman regarded the “Seven” and its forebears as a stepping stone to achieving his vision: But when he was ready to discard it Graham Nearn of Caterham Cars stepped in to rescue the “Seven” and then transform it into the core car of their business: to develop the “Seven” to make it something that would have “wowed” Colin Chapman.

The Caterham 7 exists and prospers nowadays to serve the market that Colin Chapman’s Lotus originally served: those who love the driving experience, people who want the enjoyment of driving, especially fast driving, to be provided in a car that delivers an experience unfiltered by power steering or ABS or the myriad of design elements in modern cars that divorce the driver from the driving experience.

The Caterham 7, like its Lotus forebears, is a car for the person seeking a pure driving experience. Its the closest thing you can get to a motorcycle but still be on four wheels.

Picture Credits: Lotus Cars, Caterham Cars, RM Sotheby’s, San Francisco Region SCCA.