Marcos Cars: Wooden Wonders

In the wake of the Second World War, as Britain worked her way through austerity and the process of rebuilding what had been destroyed or damaged by the not at all gentle ministrations of the Luftwaffe, a number of new small production car companies sprang up.

Of these Lotus Cars is perhaps of the best known, but there were a number of others that remained far less well known. Names such as TVR and Marcos were only really known to enthusiasts even in Britain, and were mostly unknown in the United States.

The cars created by Marcos started out being designed by a man who had spent the war years designing aircraft, notably the de Havilland Mosquito which was known as the “Wooden Wonder”: and the early Marcos cars used monocoque frames made of plywood, so these cars were also wooden wonders in their own way.

Above Video: A Mini Marcos battling with a Lotus Elan around the Goodwood Circuit in England.

In the Beginning: Jem Marsh and Frank Costin

The founders of Marcos Cars, who would go on to create a range of imaginative sports cars including the Mini Marcos, were Jem Marsh and Frank Costin. The name Marcos was simply the blending of the first syllables of each of their names – Marsh and Costin.

Not only was Marcos Cars a blending of names, but it was to be a blending of the adventurous spirit of Jem Marsh and the creative design energy of Frank Costin.

Jem Marsh was an adventurer. He ran away from school to join the Royal Navy at the age of fourteen, at the end of the Second World War, and after serving nine years in the Senior Service he found jobs working with things automotive including selling agricultural equipment and then tyres with Firestone. Jem also formed a part of the Hollywood Motor Maniacs and European Motor Rodeo, performing as a stunt driver under the stage name of “Rodeo Rod”.

Early in 1958 Jem Marsh left Firestone to take on a new adventure managing the Sporting Motorists Agency which sold performance parts for the Austin 7 cars used in 750 Club entry level motor sports in Britain. The parts were made by a man named Dan Taylor who traded under the name of “Dante” (i.e. Dan Taylor). Jem found by April of 1958 that the Sporting Motorists Agency was a company that had rather uncertain finances and so he decided to take the gamble and set up his own similar company which he called SPEEDEX Castings and Accessories Ltd. in an old hat factory in the town of Luton: he was up and running in May 1958 and made performance parts and bodywork for Austin 7’s.

Above Image: A de Havilland Mosquito.

Frank Costin spent the Second World War working for the de Havilland Aircraft Company Ltd. along with his brother Mike and so he learned a great deal about aerodynamics and the use of wood to construct lightweight yet rigid structures. After the war Mike had gone to work for the newly formed Lotus Car Company which had begun by making kits to turn boring Austin 7’s into interesting 750 Club racing cars and trials cars.

Mike asked Frank to do the design for an aerodynamic body for the new Lotus Mark VIII racing car which they worked on during 1953-1954 and from there as Frank’s reputation became well known he was asked to do a number of designs including that for the Vanwall Formula 1 car that won the 1958 Constructor’s Championship. Another example of Frank Costin’s work was the Maserati 450S Costin Zagato that competed in the 1957 24 Hours Le Mans.

Marcos Cars

Jem Marsh and Frank Costin together formed Marcos Cars in 1959. The company’s first model was the “Ugly Duckling” Marcos Xylon, which was redesigned to become the much prettier Marcos Luton Gullwing, so named because it had gullwing doors. The Luton’s sibling was the Spyder and after it came the first version of the Marcos GT, which would become the car that most people would think of when talking about a Marcos.

Dizzy and the DART

The BMC Mini, on which the Mini Marcos was based, was first introduced the same year that Marsh and Costin formed Marcos Cars, 1959. Made to replace the plethora of three wheeled “bubble cars” that had become popular in Britain in the post-war 1950’s it was small, lightweight, and quickly proved to have excellent handling and the potential to become a motorsport competitor. The Mini was also perfectly timed to become the trendy car of the 1960’s: the time when Britain became a fashion centre and London’s Carnaby Street the focal point.

The most famous pop group of that era was The Beatles and the band’s manager, Brian Epstein bought a Mini for each of the group’s members, thus helping to promote the trendiness of the car. Not only that but other popular musicians and movie stars also bought Minis making it a more and more attractive car for ordinary people to buy and drive.

One of those ordinary people who bought a Mini was Desmond “Dizzy” Addicott. He bought a damaged one second hand because he had come creative plans for it. Desmond Addicott was a professional test pilot who enjoyed motor racing and had a bit of a collection of racing cars. He was known for his sometimes eccentric ideas and that is quite possibly how he had acquired the nickname “Dizzy”. With the BMC Mini having become a 1960’s icon Dizzy bought a damaged second hand Mini van for £5 and with help from a friend named Paul Emery replaced the damaged bodywork with a streamlined aerodynamic one. His plan was to take his new creation racing and he inscribed the word “DART” on the front: this standing for “Dizzy Addicott Racing Team”.

The idea of an aerodynamic sports/racing car based on the humble Mini captured Jem Marsh’s interest and he got together with Dizzy Addicott with plans to begin production of a fibreglass bodied sports car inspired by Addicott’s car. As it turned out Jem and Dizzy did not finish up doing the project together but Jem Marsh and Marcos Cars used the DART concept as the basic inspiration for their own Mini Marcos design.

Dizzy Addicott did not want to invest the considerable time and effort to put his Mini DART into limited production and so he sold the Mini DART concept to Jeremy Delmar-Morgan who re-named it the “Mini Jem” which was put into limited production by his company in North London.

Dizzy Addicott’s first love was flying and he redirected his energies into his aviation career, joining British company Vickers as a test pilot. Dizzy also did air display work and flew aircraft for a number of movies including “The Dirty Dozen”, “The Blue Max”, and “Memphis Belle”.

The Mini Marcos Mark I Goes Into Production, and to Le Mans

Jem Marsh’s idea for a Mini Marcos “GT” was somewhat different to that originally created by Dizzy Addicott. Jem Marsh and his team at Marcos created a fibreglass monocoque body shell that completely replaced the steel BMC Mini one. The team included Brian Moulton who did the design work along with Malcolm Newell who was the pattern maker. The Mini Marcos Mark I was manufactured and sold as a bodyshell kit.

This monocoque fibreglass body shell was made so that the customer could simply bolt the engine, transmission and suspension parts from a standard BMC Mini to it to build the car. The one part that was different was the fuel tank, which had to come from a Mini van. The kits were limited production items with about 150 of the Mark I kits being sold. Being based on the Mini van rather than on the Mini sedan the wheelbase of the kit car Mini Marcos was a bit longer than the Mini sedan which helped it have more stability.

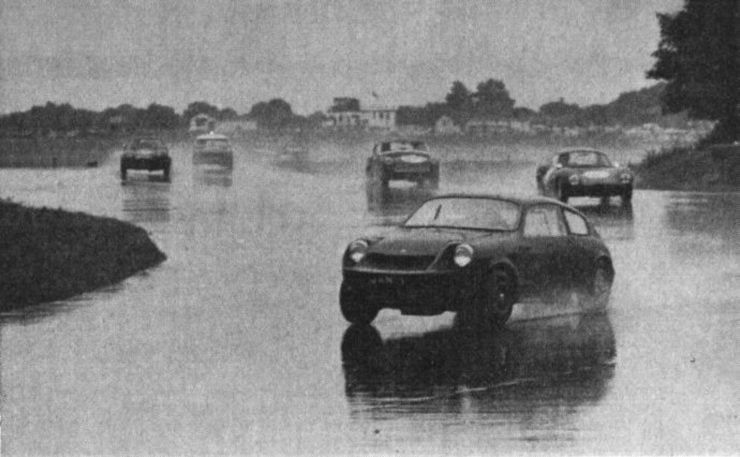

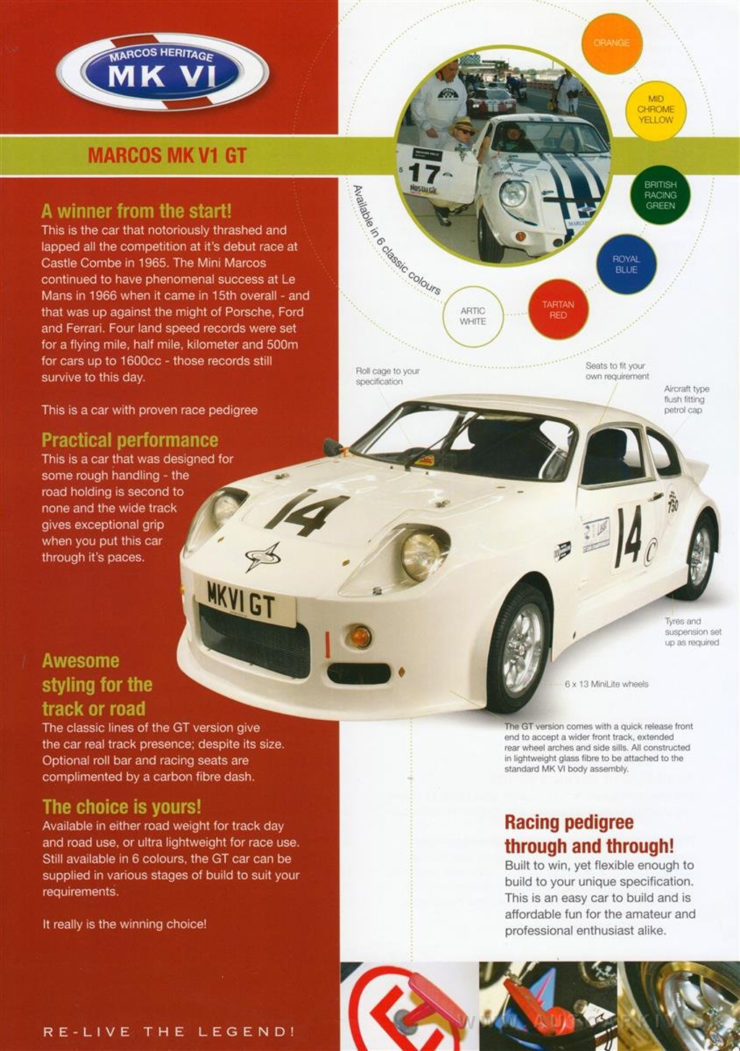

The Mini Marcos made its racing debut at Castle Combe racing circuit in September 1965. Painted fire-engine red and driven by Geoff Mabbs it won by a margin of 88.1 seconds having lapped all bar one of the other competitors. This was all the more remarkable because the car had been freshly completed the night before and Geoff Mabbs only had seven laps practice in it before the rain soaked race began. This car had been entered by Janspeed Engineering and was fitted with a Group 2 1,293 cc Mini Cooper S engine.

Following the victory at Castle Combe that same Mini Marcos was shown at the 1966 Earls Court Racing Car Show and from that showing arrangements were made to enter a Mini Marcos in that year’s 24 Hours Le Mans. Entering a car in the Le Mans race depended on obtaining an invitation from the Automobile Club de l’Ouest (ACO) and they were not particularly receptive to having the British Marcos enter. What was needed was a “work around” and that took the form of setting up a French entry. To make a Mini Marcos a “French Entry” William Dulles Motor Accessories became involved and he and Jem Marsh set up a European distribution company for the Mini Marcos: Dulles Components Ltd. and a Mark I Mini Marcos was taken to dealerships in Europe successfully gaining some orders for the car.

In order for the car to entered in the race it had to be road registered in France and by far the easiest and cheapest way to accomplish that was to buy a used Mini van that was already registered for the road in France and use it for its chassis plate and registration. The Le Mans Mini Marcos was built by Jean Louis Marnat’s team using a body shell transported to France by Billy Dulles on the back of his Mini utility/pick-up. BMC Abingdon Special Tuning Department agreed to supply two engines for the car on condition that they not be attributed to BMC as they did not want negative publicity if the engine or transmission failed during the Le Mans campaign.

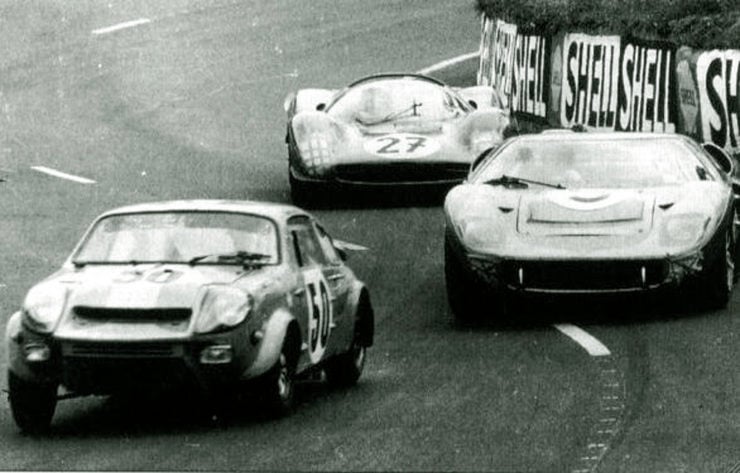

Driven by a French team comprising Jean Louis Marnat and co-driver JC Ballot-Léna the Mini Marcos went around the Circuit de la Sarthe enough times in the 24 hours to make the distance qualification and became the only British car to finish the event that year, in fifteenth place overall, and fifth in the 1.3 litre Prototype class: a great result for Marcos and the French team that made it happen. The Mini Marcos had also proved itself to be capable of 130 mph hurtling down the Mulsanne Straight: a speed it would improve on the following year, clocking 146 mph, but sadly only completing eleven laps before the oil pump failed forcing the little Mini Marcos out of the race.

The Mini Marcos Mark II and Mark III

In 1967 Jem Marsh and his team decided to refine the original Mini Marcos design. The style changes for the Mark II included semi-circular wheel arches to replace the notched style of the Mark I, a recessed fuel filler, and a slightly larger front license plate panel.

The main disadvantage of the original Mark I and Mark II Mini Marcos for use as a road car was the fixed rear window which meant access to the rear luggage storage space was awkward. This was corrected in the Mark III model which was given an opening rear hatch as an optional extra. The Mark III Mini Marcos sold in much larger numbers than its predecessors and it became the first of the Mini Marcos to gain homologation when a batch of fifty were made by Marcos at their Bradford-on-Avon facility. Not only that but the Mini Marcos began to be made under license by other companies in Ireland, and South Africa. There were also copies of the Mini Marcos/Mini Jem concept made by Taylorspeed in Adelaide, Australia.

Financial Collapse and the Birth of the Mark IV

The Mini Marcos was not Marcos’ only model, the two seater Marcos GT was the flagship car and Marcos wanted to compliment that with a new four seater sports car. The new Marcos Mantis was built around a square tube frame with a fibreglass body and was powered by a Triumph 2.5 PI inline six cylinder engine with Lucas mechanical fuel injection. The new Marcos Mantis had styling that was “love it or hate it” and few customers seem to have been attracted by it with the result that only thirty two were sold.

By 1971 with the lack of hoped for sales of the Mantis and Marcos’ move to a more expensive production facility the company was placed under too much financial strain and had to cease trading. Marcos Cars Components Limited was purchased by Corsley Garages, which was owned by heir to the Johnnie Walker whisky company, Rob Walker of Rob Walker Racing Team fame. Rob Walker renamed the company Marcos Limited and set about improving the Marcos models, creating the significantly improved Mini Marcos Mark IV.

The Mini Marcos Mark IV was based on the Mini Traveler and so was longer and slightly taller giving it more interior room improving the driving position and making the car suitable for taller drivers. It was fitted with an opening rear hatch as standard equipment and also had the sheer luxury of wind-up windows, so it was a significantly improved proposition as a road car by comparison with its predecessors.

The Mini Marcos Gets the Midas Touch

In 1975 an agreement was made between Marcos Limited and D & H Fibreglass Techniques for D & H to manufacture the Mini Marcos, and initially they continued production of the Mark IV.

It would be the Mini Marcos Mark IV that would prove to be an unbeatable speed record setting machine. 1977 saw the creation of the TransXL International Mini Marcos Mark IV. This special competition oriented version of the Mark IV was powered by a 1,480 cc Type A engine custom built by John Mowatt, special gearbox and limited slip differential. In the suspension were rose joints while the disc brakes were fitted with magnesium calipers. This car, driven by Steven Roberts set four up to 1,600 cc land speed records; Flying Mile, Half Mile, Kilometre, and Half Kilometre. Amazingly these records stand unbroken up to the present day.

The TransXL was not only quick in a straight line but in other competition it gained podium places in 74 events from 98 starts; 36 first place, 27 second place, 11 third place. After this succession of victories the diminutive little road bullet was displayed at the London Science Museum and then at the National Motor Museum at Beaulieu.

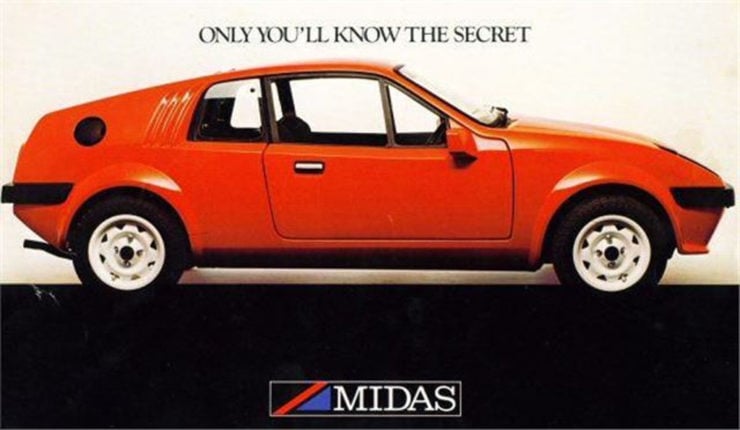

While the performance credentials of the Mini Marcos Mark IV were impeccable the head of D & H, Harold Dermott, wanted to get the styling of the car both modernized and refined. He could see the potential for improvement and commissioned Richard Oakes to create a new body style. They decided to give the new car the name “Midas”, perhaps thinking that the new design had given the car a “Midas Touch” that would make it appealing to a larger audience.

This car was mechanically mostly the same as the Mini Marcos but did away with the rear BMC Mini subframe and instead used a beam onto which the rear trailing arms were mounted. The Mini Midas was first shown at the 1978 Performance Car Show in London and it turned out that it had indeed been given a “Midas Touch” as the orders began to flood in.

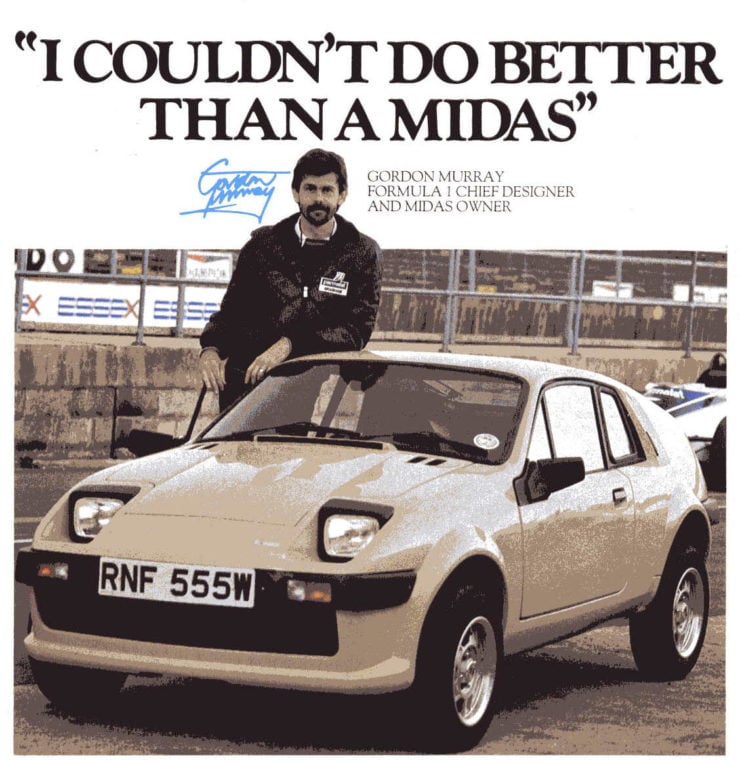

The Midas caught the attention of Gordon Murray of the Brabham Formula 1 racing team, a man who would later go on to design the MacLaren F1, and his suggested improvements to the car were incorporated in 1981. Demand for these quick and now rather pretty little cars was by this time more than D & H could manage in their existing factory so they made a move to a new larger factory in Corby, Northamptonshire and as they did so renamed the company Midas Cars Ltd.

By 1985 it became necessary to redesign the Midas to enable it to use the parts from the more modern Morris and MG Metro. The redesign work was again done by Richard Oakes and the new model sported larger windows, wider wings, and a restyled front end. The new car also had improvements to its aerodynamics courtesy Gordon Murray. D & H wanted to be able to sell complete cars as well as kits and so the new model was put through the ECE12 crash test and successfully passed.

The future for the Midas looked good until 1989 when the factory was destroyed by fire, an event that caused production to cease. With the ending of production of the Midas D & H was sold to Pastiche Cars, a company that did not last long before going into receivership, but under the terms of the original agreement between Marcos Ltd and D & H the rights, moulds, tools and jigs for the Mini Marcos reverted back to Marcos Ltd.

Midas Cars did not end there however and were owned by GTM before being purchased by Alternative Cars Ltd. in 2004. Midas Cars are currently in production.

The Mini Marcos is Born Again Twice: the Mark V and Mark VI

By 1991 the Mini Marcos was revised into the Mark V version which boasted nothing less than an optional elm or walnut dashboard to make your Mini Marcos just as stylish as a Jaguar or Aston Martin, well, sort of. The Mark V boasted 13″ wheels and a wider track along with the wind-up windows an optional sun-roof and even air-conditioning. Not only were there improvements but the new Mini Marcos Mark V was exported to Japan as a fully built car, a first for the car in its 25th Anniversary year. Production of the kits continued until 1995 and then it seems the demand for the kits was so small that production was ended.

Marcos went into receivership in 2001 and the rights, tooling, moulds, jigs and plans for all Marcos models were acquired by Marcos Heritage Spares Ltd.

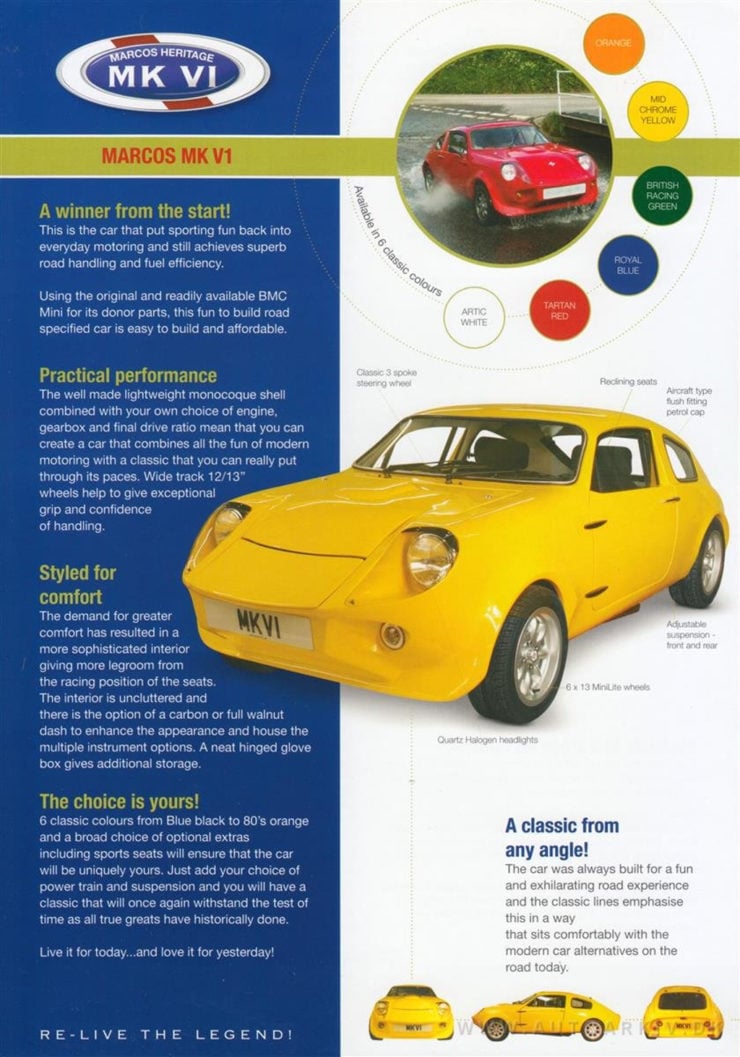

Marcos Heritage Spares list two models of the Mini Marcos available in kit form, the Mark VI, and the Mark VI GT. These kits from Marcos Heritage Spares require the use of original Mini parts, usually obtained from a donor car. As the Marcos Heritage fibreglass body replaces the original steel Mini monocoque body this can be a good project for a Mini that has rust in the bodywork but which has good, useful mechanical parts. What will be needed are the sub-frames however and if these are rusted or damaged then new ones will be needed for the construction of the kit.

The Mini Marcos kits from Marcos Heritage Spares comes in three stages which a customer can purchase progressively as they work on their kit assembly or all at once.

Epilogue

So it is that the Mini Marcos has proved to be too good an idea to die an ignominious death and instead it just keeps on keeping on. This little kit car that made its debut back in 1965 with a convincing victory on a very soggy race track is still capable of delivering hair raising excitement and a driving experience second to none. This is a car that is a bit like a time machine, it takes you back to a bygone era when London’s Carnaby Street was the fashion capital of the world and The Beatles were a new pop sensation. And yet it is also modern enough to drive on twenty-first century roads – or race tracks – and it will still deliver performance that will both satisfy the driver, and impress those who see the car in action.

So for those who bemoan that “They don’t make ’em like they used to”, the Mini Marcos proves them wrong. It is made the way it used to be made, and if properly set up it delivers the same or better performance than the car that carried Geoff Mabbs to victory at Castle Combe.

Picture Credits: Marcos Cars, Midas Cars, Marcos Heritage, Diana Varga @ RM Sotheby’s, De Havilland.