This is a Douglas DC-8 engine cowling that has been converted into a desk – with a large curved work surface and a cutaway section to allow you to roll an office chair into it.

We’ve seen a number of companies designing high-end furniture and other items from retired aircraft parts, from sections of cowling to seat material, engine cowlings, and even elevators.

History Speedrun: The Douglas DC-8

Douglas entered the jet age a little later than Boeing, but with a clear brief to protect its hard-won airliner franchise and give trunk-line carriers a modern, transcontinental aircraft. The company had watched Boeing win the USAF tanker contest with the KC-135, then pivot that know-how into the 707.

Douglas responded in 1955 with the DC-8, built at Long Beach and aimed directly at the same market. The prototype rolled out in April 1958 and flew on May the 30th of that same year – after an intensive test program, certification followed in August of 1959 and service began on September the 18th, 1959 with Delta and United. It was a measured, Douglas-style entry – conservative systems, a well-designed structure, and the cabin cross-section design airlines already liked.

Early DC-8s used Pratt & Whitney turbojets, later on the Series 40 adopted Rolls-Royce Conway turbofans – the Conway was the first turbofan to enter airline service, debuting on BOAC’s 707-420 in May of 1960, and Conway-powered DC-8-40s followed later on in the same year. The definitive short-body arrived as the Series 50 with P&W JT3D low-bypass turbofans, better fuel burn, and the factory “Jet Trader” cargo door option that previewed the type’s second life.

In a bit of flight-test lore, a DC-8-43 briefly went supersonic in a controlled dive on August 21, 1961 to gather wing data – an airliner first.

Capacity and range requirements soon resulted in the “Super Sixties.” The 61 series stretched the fuselage dramatically for high-density domestic work, the 62 series gained span and range for long overwater routes, the 63 series combined the stretch with the long-range wing.

These were the money makers for Douglas, arriving just as air traffic was booming. When noise and fuel economics tightened in the 1970s, Douglas and GE offered the series 70 retrofit with CFM56 turbofans, which cut noise substantially and extended useful life – especially for freighter conversions. Across all variants, 556 DC-8s were built from 1958 to 1972 before Douglas (by then McDonnell Douglas) shifted to the wide-body DC-10.

On paper the DC-8 reads like a classic – four engines, three-crew cockpit, narrow-body fuselage seating roughly 150-220 people depending on series and layout, and a structure that tolerated stretching, doors, and new engines without drama.

In service, it did the work – coast-to-coast hops, intercontinental sectors, and later on in its life, night cargo. Delta’s early records show how quickly the jet shrank the map, United leaned into the stretched variants, and many airframes finished their careers hauling freight.

One even served the world of science – NASA’s heavily instrumented DC-8 supported atmospheric missions for decades and flew its final research sortie in April of 2024 before retirement.

The Douglas DC-8 Engine Cowl Desk Shown Here

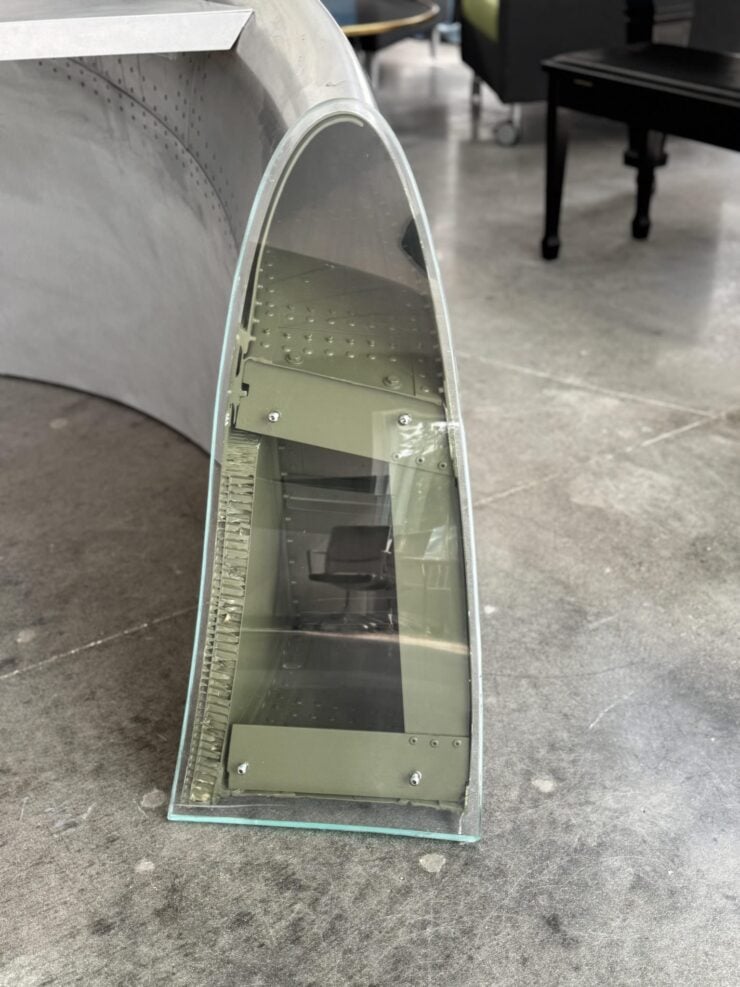

This custom-built desk was made from an engine cowl that was originally fitted to a Douglas DC-8 airliner.

Measuring in at 68 inches in diameter and weighing around 500 lbs, this desk combines polished and painted metal surfaces with visible “NO STEP” warnings and yellow service decals that preserve its unusual aircraft origins. Transparent acrylic panels have been fitted to both ends of the cowl, allowing a clear view of the original internal structure.

The work surface sits approximately 29 inches high, mounted below the upper lip of the cowl, with two rear grommeted holes for cable management. The base is designed to rest directly on the floor using fixed glides, ensuring stability despite its substantial weight.

It’s now being offered for sale out of San Diego, California at no reserve on Bring a Trailer and you can visit the listing here if you’d like to read more about it or place a bid.

Images courtesy of Bring a Trailer