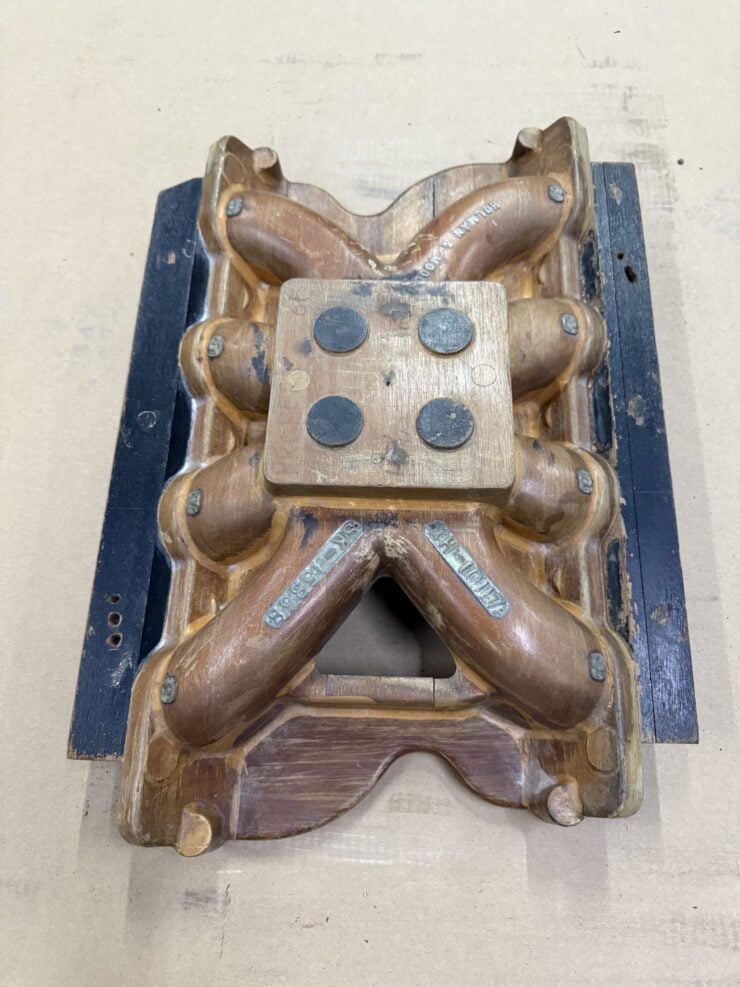

These are the original mahogany sand casting patterns that were used by Holman-Moody in the 1960s to manufacture the alloy intake manifolds for the legendary Boss 429 V8.

Patterns like this are used during the sand casting process to create complex 3D parts, commonly from aluminum alloy or iron. These wooden patterns are used to create the correct shape in the sand mold, the sand mold is then filled with molten metal which takes the shape and cools in place, after this the sand is broken away and you have your completed part.

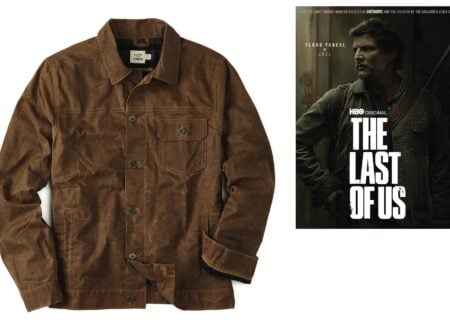

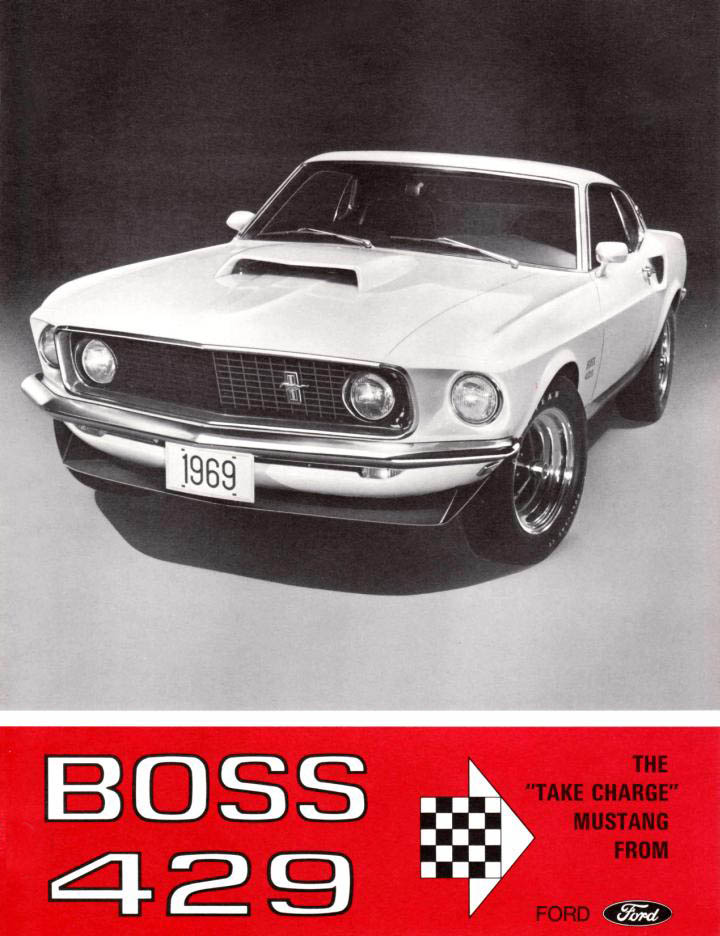

The Boss 429 V8 was used in the Boss 429 Mustang which debuted in 1969, and left production in 1970. As the name implies, the Boss 429 was powered by the big block Ford 429 cubic inch (7.0 liter) V8, the car was ostensibly created to homologate the engine for NASCAR racing, however it also found a home on drag strips due to its prodigious acceleration.

Ford had used a big block V8 in the Mustang before with the Shelby GT500, though this car was equipped with the 428 cubic inch V8. The Boss 429 was released alongside the Boss 302 Mustang, this 302 cubic inch (5.0 liter) V8-powered model was designed to homologate the engine displacement for Trans Am racing.

Holman Moody, a legendary race car engineering company that often worked closely with Ford, was deeply involved in the development of the 429 Boss V8 along with the engineers in Ford’s racing division. The final engine design would use lightweight aluminum Hemi-style heads, an aluminum intake manifold, a 35 CFM Holley carburetor, and a high-performance cam along with a number of other refinements.

In street tune the engine was capable of 375 bhp at 5,200 rpm and 450 lb ft of torque at 3,400 rpm. Many owners soon realized that the engines responded well to tuning and the fitment of aftermarket parts, and not long after release there were examples producing well over 400 bhp.

The mahogany wood sand casting patterns you see here were produced by Buddy Bar Casting and consist of four individual pieces that fit together. The identification numbers are visible on the upper patten.

These parts were previously sold by Holman-Moody in the late 1970s during a liquidation sale, and correspondence from Lee Holman, the son of co-founder John Holman, it included in the sale.

It’s important to note that these are said to be incomplete, so some sections of the pattern are missing, however the important top piece is included – so it would make a fantastic display and conversation piece.

If you’d like to read more about these unusual Holman Moody artifacts or register to bid you can visit the listing here. They’re being offered for sale on Bring a Trailer out of Minnesota Lake, Minnesota with no reserve.

Images courtesy of Bring a Trailer