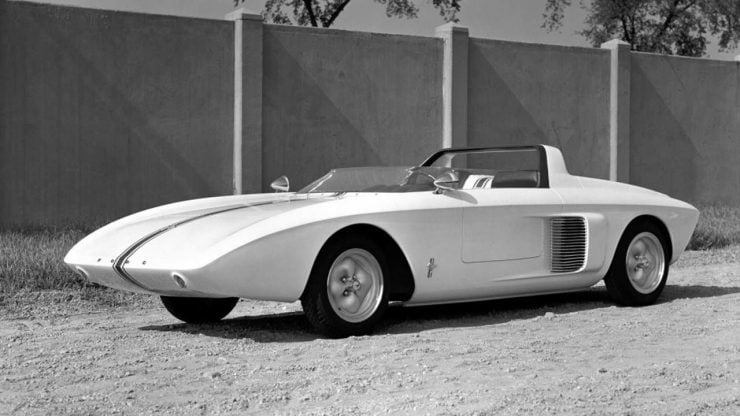

The 1962 Ford Mustang I is a concept car that shared almost nothing with the car that would go on to wear the Mustang badge. It’s a bit of an open question as to what might have happened if the Mustang that was offered to the American public was similar to the early concept car – a small, lightweight, mid-engined sports car capable of challenging the Corvette.

I’ve included a full transcript of the film below for those of you who can’t watch the film, or would just prefer to read through at your own pace. There are also more images at the bottom.

Full Film Transcript:

Within the giant industrial complex of the Ford Motor Company in Dearborn, Michigan is the Research and Engineering Center. Here a concentration of engineers and stylists each year create the Ford family of fine cars, they also explore new concepts for automotive designs from new ideas and develop very special kinds of research vehicles to prove out new features and new ideas.

You are about to see the results of one such research effort.

This is the spirit of the wild mustang. Bred into a fine machine – there is only one but it has spurred inquiry and comment from across the nation and from many other parts of the world.

Actually the Mustang is a research vehicle conceived and brought to the stage of development testing by a group devoted exclusively to evaluating the feasibility and desirability of new automotive design concepts – concepts that might be applied to future production cars.

Why a sports car? The sports car is far from being new in concept true but over the years it has influenced the development of passenger cars in all categories and this type of vehicle is particularly suited to the plans of Roy Lunn – manager of the Vehicle Concepts Department.

He explains that his group in collaboration with Ford’s advanced stylists have in mind certain features, potentially useful in a variety of models, which could best be developed and proved out in a sports car type vehicle. He is thinking of aerodynamically clean body shapes with improved seating positions. Lighter weight but stronger body structures. Mid-ship engines with proper cooling and better handling qualities, and road-holding ability.

The other group in the center associated with the creation of this research vehicle was the Advanced Styling Studio, and it was here the functional aerodynamic body was designed. The low drag clean front end was shaped and a safety roll bar was incorporated in the styling concept. The efforts of the styling and engineering groups were given executive support by the vice president in charge of styling Eugene Bordinat and the vice president in charge of engineering Herb Misch.

Together these Division heads endorse the project.

Having selected a sports car configuration Roy Lunn’s group set themselves additional objectives.

They would design a high performance two-seater that would conform to racing category 9 of the Federation Internationale de l’Automobile and to Sports Car Club of America regulations.

Because it was purely an experimental car the engineers chose to use a welded tubular steel spaceframe for a strong, light weight for the Mustang.

The test measurements for the frame were made on an accurate scale model that provided data easier and faster than calculating the many stresses. The model is detailed down to the attachment brackets for the front and rear suspension members.

The actual frame was fabricated in California by the custom car builders Troutman and Barnes. In addition to being both lightweight and strong the space frame can be built quickly. The engine and transmission pose no serious problem.

Ford’s recently developed V4 engine and four speed transaxle combination designed for front wheel drive in the Ford Taunus 12M proved a perfect solution.

While unsuited for forward mounting because of the Mustang’s small frontal area the engine moved to midships, not only made reduced final area possible and therefore allowed better aerodynamic form, but made for excellent weight distribution because it could be placed forward of the rear axle with no change in the drive train.

With modifications, new cam, distributor, higher compression head, intake manifold, valve springs, and carburetors, this engine had excellent performance possibilities.

The design of the clean small frontal area body that would be two seater and have a mid-ship engine of course fell to styling and after many preliminary drawings the final design evolved.

Clean entry.

Stylized rollbar.

Functional air scoops at the sides.

A body that housed and reflected the car’s advanced engineering ideas.

Of course the car needed a stylized embellishment to capture the spirit of the Mustang in its quest and this was rendered first on paper.

Then in clay and wood.

And finally in metal.

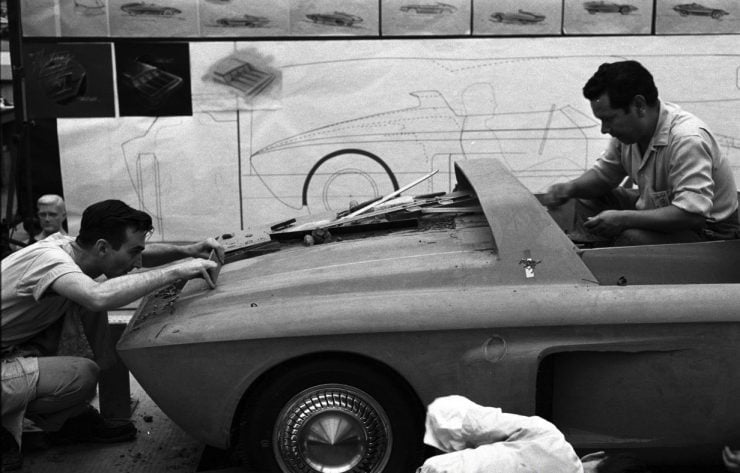

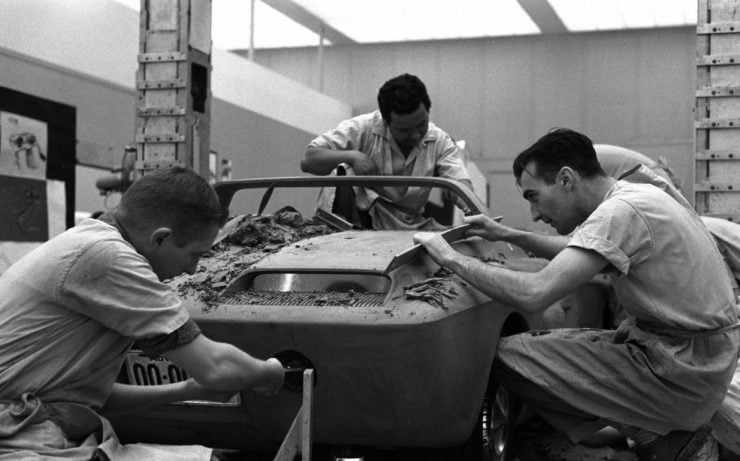

The special body it was first developed in clay, starting with a wooden form called an armature which helps make a faster, lighter, and less expensive model. Special hot modeling clay is pushed and formed over the armature because when cool the clay becomes firm and hard, perfect for precise modeling.

A special bridge mounted on rails ensures that each contour of the side being modeled is accurately transferred to the other side.

Skillful hands and watchful eyes of the stylists, ensuring that every long sweeping curve is true to the evolve design.

When the clay was completed it was covered with a special plastic sheeting called “Die Knock” which looks like metal, yet can be applied in a fraction of the time it would take to do a similar job in the paint shop

The American colors white and blue were chosen for the Mustang.

When Herb Misch and Eugene Bordinat saw the completed clay, they were delighted.

With the clay approved a female plaster mould was formed the clay was first coated with a partigen, then with a lime slurry.

Then covered with excelsior dipped in plaster.

When hard these plaster moulds were all that were removed.

The fiberglass body form was made by coating them with resin after properly treating the plaster surface then applying glass cloth over the resin coating. Smoothing the cloth to fit the contours.

After several layers of cloth and resin had been laminated, the forms were pushed back into place.

When all the forms were joined and the fiberglass and resin laminate had cured, the molds were removed and the accurate fiberglass body form was finished.

After being cleaned up and painted, the fiberglass body form was subjected to a wind tunnel tests.

The wind tunnel tests confirm the car’s clean aerodynamic design and prove the effectiveness of the side intake vents which are located at high pressure zones in the air stream.

Following the wind tunnels tests, the fiberglass body form was sent to Troutman and Barnes.

Complete plans, specifications, and all component parts accompany her. Roy Lunn checked every part with the builders to insure that everything would function properly.

The body was designed as a semi-unitized construction with the frame, which was now completed.

The aluminum tank was installed as were the one piece special seats that were designed to be an integral part of the body and frame.

The remaining body panels were formed under the under the watchful eyes of these expert west coast bodybuilders.

Their talented hands and hammers fixed the aluminum into precise and graceful shapes.

When finished each of the aluminum panels was carefully fitted to the fiberglass body form to ensure accuracy before they were to be joined and welded to the frame.

The completed aluminum body was flown to Dearborne, where the Mustang was finally assembled.

First of the advanced features to be installed in the car was the adjustable pedal mechanism, providing for varying sizes of drivers.

Brake and clutch master cylinders were mounted on the same unit and connected to the body by flexible hoses.

A one piece competition windshield was put in place.

Large, easily visible instruments were mounted in a padded dash with a built in grab handle.

To cool the engine two special radiators were installed. Each was equipped with a thermostatically controlled fan. And each was just behind a side intake vent.

Including the seats as a part of the body structure was an idea likely to see application in many kinds of future production cars. In addition to strengthening the body allowed clean lightweight seat cushions with built-in head rest that easily could be fixed to the body. And safety belts which readily could be made reachable.

Special A-frame independent suspensions were designed for all four wheels.

Those in front were equipped with nine and a half inch disc brakes adapted from the Ford Consul manufactured in England.

Combined spring and shock absorber units were installed all round.

In the rear, standard nine inch drums also from the English Consul, were fitted.

And a new and unique steering assembly was designed which has a rack and pinion steering gear, a flexible shaft, and three inches of fore and aft adjustment.

The retractable headlights, spare tire, battery, and gas tank are up front.

Access to both front and rear compartments was provided.

Front hinged doors on either side.

Exhausts through the rear and all necessary lights were provided. And so the car was complete – ready for testing.

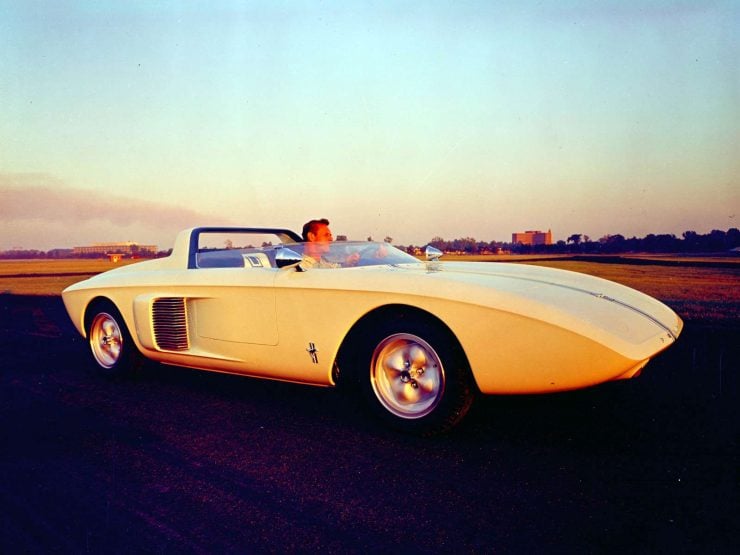

The faces of Ford’s top executives reflected their surprise and delight in seeing this new car put through its paces for the first time.

There was good reason for their interest and pleasure advanced features made a lot of sense, they proved completely functional, added styling appeal, and could be applied to many of the company’s future products.

Although advanced features incorporated into this development are usually kept as company secrets for competitive reasons, Ford recognized that this particular research vehicle, being in sports car configuration would have wide public appeal.

The decision was made therefore to show the car publicly as a candid example of advanced automotive engineering and styling an example of the exciting kinds of projects in which Ford automotive engineers and stylists are engaged.

Stirling Moss greeted the crowd at the premiere showing of the Mustang at Watkins Glen, New York on a leisurely lap before the start of the United States Grand Prix.

Car and Driver Magazine was one of the first of the many publications to recognize the engineering and performance potential of the Mustang, and its technical editor Jan Nordby was invited to test the car. Roy Lunn went along to answer questions.

Jan – “I would like some kind of support for my accelerator foot”

Garbled

Roy – “This is a thing we’re going to make”

Jan – “But the response is beautiful”

The other magazines shared Jan’s enthusiasm:

“The Mustang is a V4 for fun”

“The car is a real eye kit and the features are all functional”

“The Mustang is a very serious engineering study”

Its fresh new appearance, its unique styling, generated immediate interest wherever it was seen.

Here at the University of Miami the Mustang pulls up in front of the student union and is engulfed by students who are seeing the car for the first time.

As everywhere, they are full of questions, want to know all about a car they had only heard about.

The features of the car are explained starting with the twin exhausts that go through the rear body. The twin engine ventilating grilles vent hot air to leave the engine compartment and the twin horizontal rear lights the house left and right turn indicators. And stop lights.

The Mustang emblem is also the latch that releases the rear deck lid.

Derived from the new German Ford Taunus 12M engine this road version has a single carburetor, high speed cams, 11:1 compression ratio, a 60 degree V4 block of 92 cubic inches, alternator, twin radiators, four speed synchromesh transmission and transaxle, with independent suspension and drum brakes.

The radiator intakes are located at high pressure areas on the body. For normal operation of the cooling is via ram effect otherwise the thermostatically controlled fans come into play.

The cockpit has a complete set of color coded instruments in its padded dash including tachometer, oil pressure gauge, ammeter, and water temperature indicator.

The steering wheel has three inches of fore and aft adjustment.

The pedals are adjustable and can be moved back and forth four inches by means of an easily accessible handle.

The gear shift lever is located on the center console and operates four fully synchromesh forward gears and one reverse. The handbrake is of the fly off type.

Horn, choke, and directional signal control are also on the console.

The wheels are magnesium reduce unsprung weight and the tires 550 x 13s.

The spare wheel and tire are up front where their weight will do the most good. As are the floor-mounted battery, the rack and pinion steering gear, thirteen gallon fuel tank with flip cap and horns on either side.

The master brake cylinders are a part of the movable pedal unit and move with it.

For the cleanest possible front entry the headlights swing through one hundred eighty degrees for night for height above the road, and go flush for daylight driving.

Similarly the license plate can be flipped down for normal driving or folded away for racing.

As a car the Mustang demonstrated excellent road holding ability on the closed circuit road course at Daytona Beach.

It’s fully and fully adjustable suspension was responsible for its optimum road handling and road holding characteristics.

On road courses the car further demonstrated its versatility.

And on the high-speed oval it proved capable of impressive performance for a car with piston displacement of one and a half litres.

Garbled.

Here at the Daytona Speedway Bill France watches the Mustang go by, clocked at 120 miles per hour at a comfortable 6100 rpm.

Yes the Mustang turned out to be the kind of car that dreams are made out of but a dream it must remain for this car was created by engineers and stylists only to prove out the feasibility and desirability of certain new design features.

A number of the advanced features represented in the Mustang along with its performance and handling characteristics proved out really well.

Although there are no plans to bring the car into production you will undoubtably see some of its features incorporate other cars we do bring into the market. That was the purpose of the Mustang project a pioneering expertmental development by Ford engineers and stylists.

END