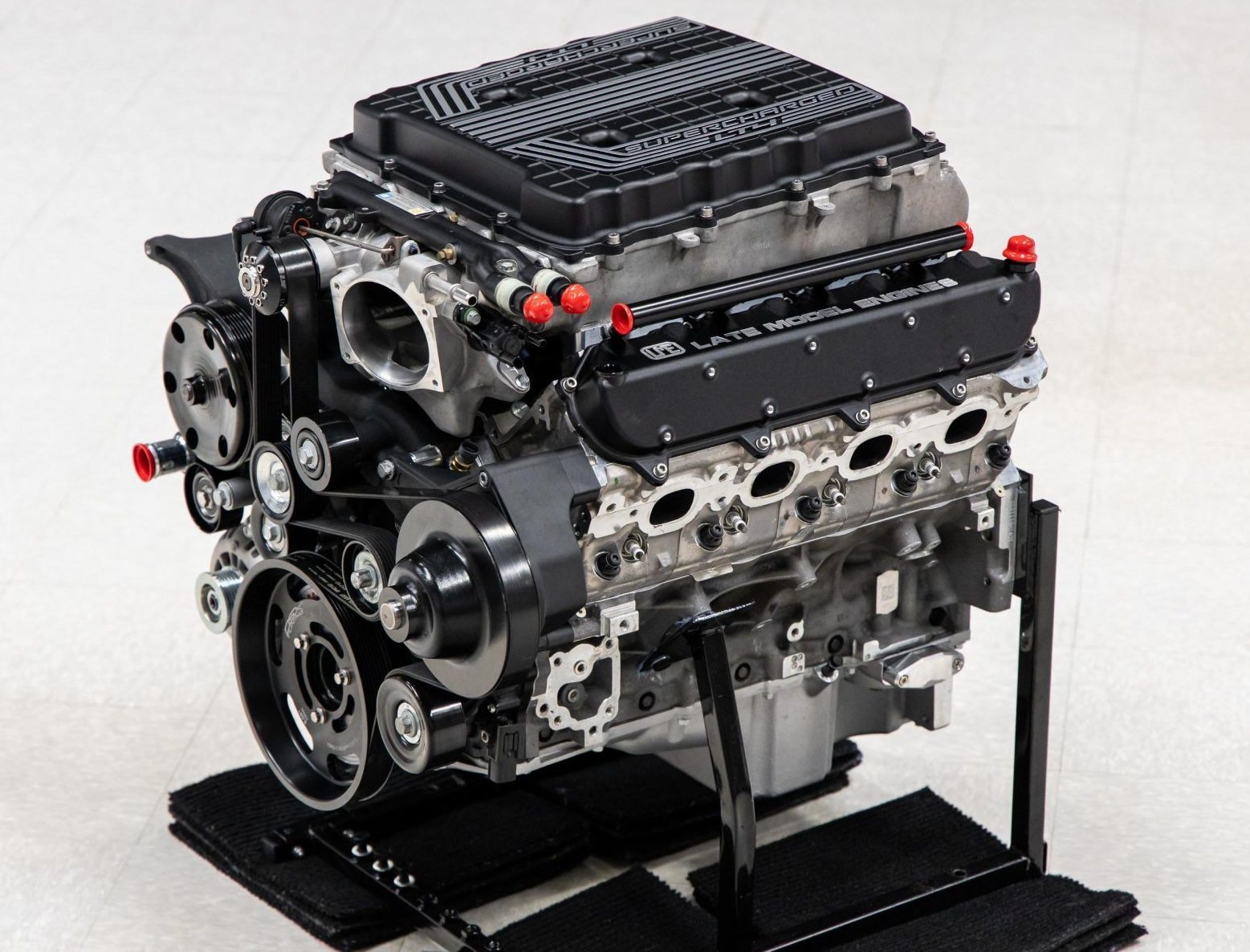

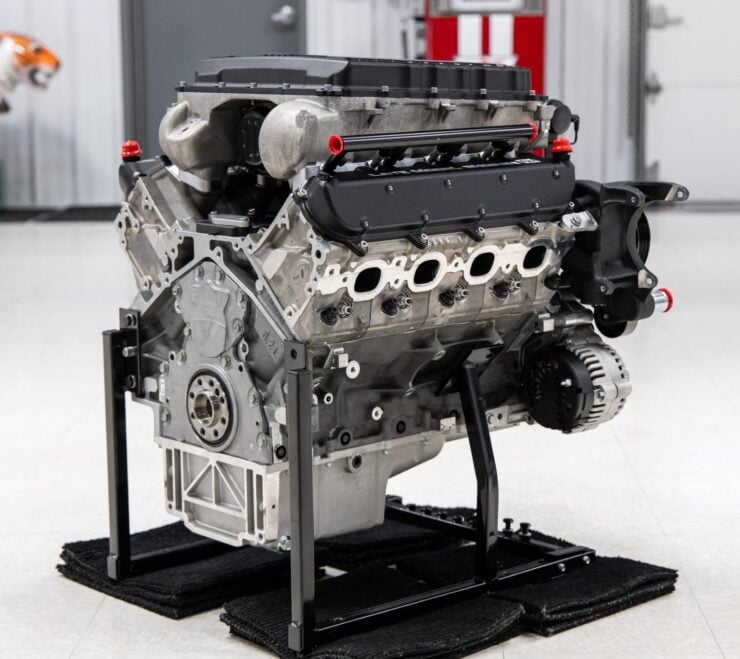

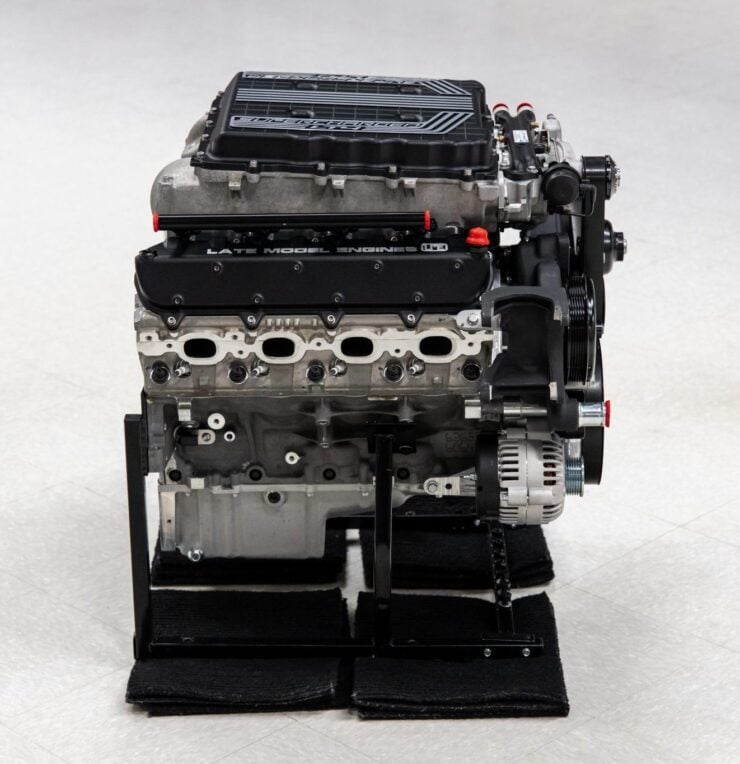

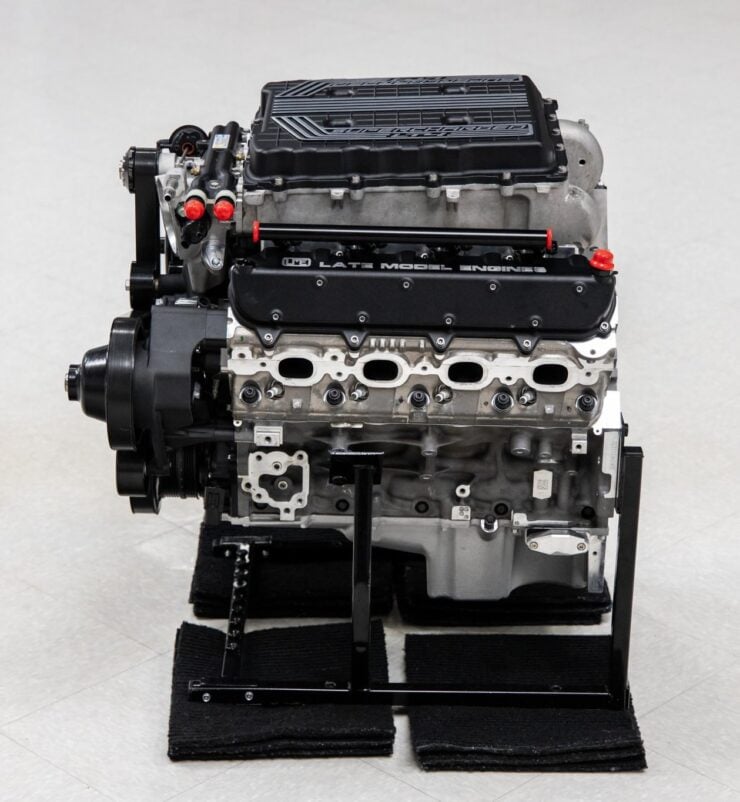

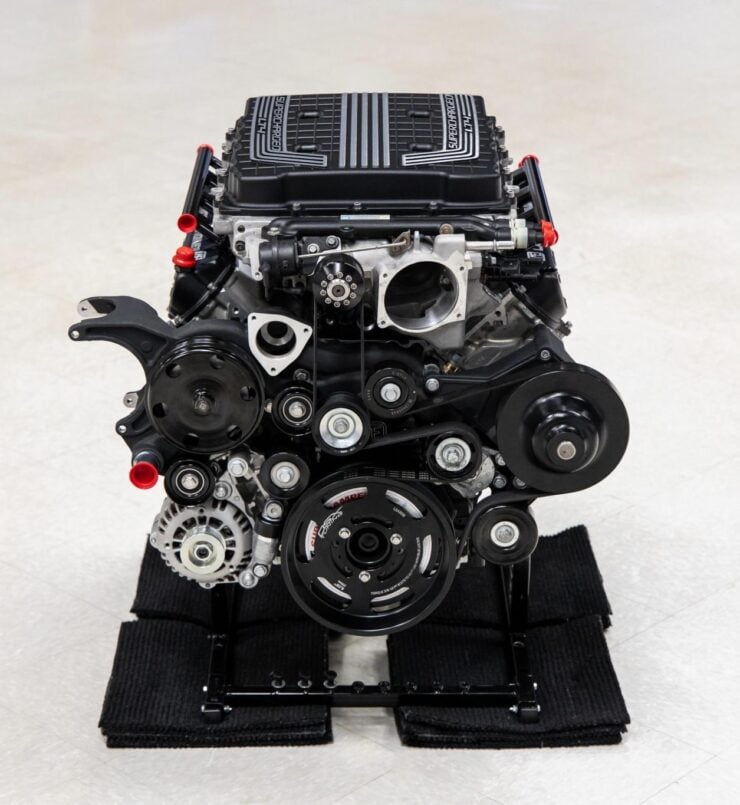

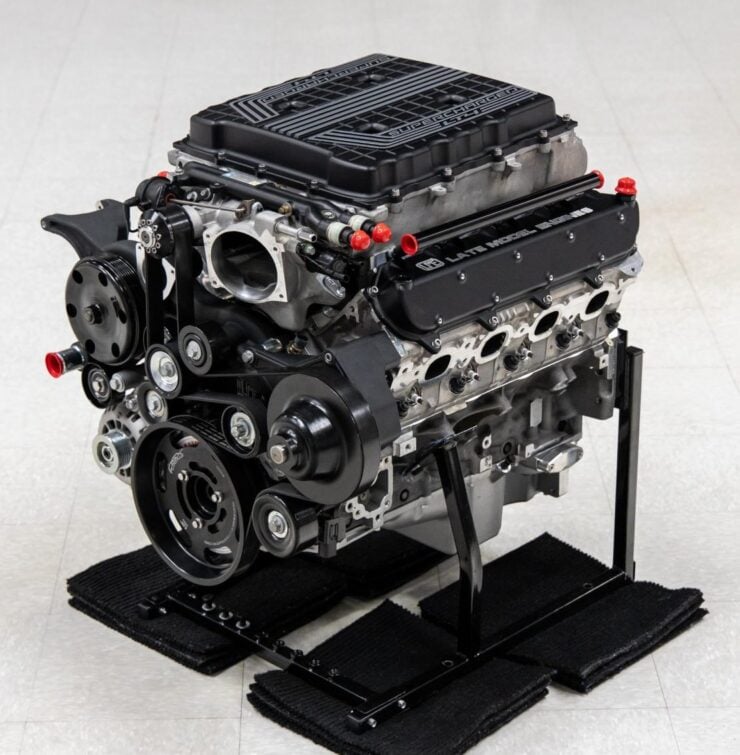

This is a Chevrolet Performance LT4 crate engine that was modified by Late Model Engines of Houston, Texas. It now produces a dyno-proven 821 bhp and 797 lb ft of torque, and the engine is tuned to run on 93 octane pump gas.

This LT4 was built by Aaron Kurt of Late Model Engines and it’s never been installed into a vehicle – the only time it’s been run is on the dyno for testing. It’s now being offered for sale – offering over 200 bhp more than the factory version.

History Speedrun: Late Model Engines

Late Model Engines (LME) is a performance engine builder based out of Texas – they’re known for producing some of the most highly-respected LS and Gen V LT engines in the United States. The company was founded in 2003 and it operates from its state-of-the-art facility on Aldine Western Road in Houston, where it machines, assembles, and dyno-tests complete engines for street and competition use.

LME specializes in high-performance Chevrolet-based V8s, offering complete longblocks, shortblocks, and custom billet parts including intake manifolds, valley covers, timing chain guides, and dry-sump hardware. They also produce CNC-ported cylinder heads for LS, LT, and Gen III Hemi platforms – allowing the company to tailor airflow and compression ratios for specific applications.

Inside the shop, LME has multiple CNC block machining centers, Sunnen honing systems, a Hines electronic balancer, and a SuperFlow flowbench paired with an EFI-capable engine dynamometer.

This equipment allows every stage of the build – from block prep to head porting, balancing, and dyno validation – to take place in-house, ensuring consistency from one engine to the next.

Company owner Bryan Neelen and his small team have always emphasized a focus on quality over sheer volume, and he describes the operation as “the benchmark for performance and racing LS and Gen V LT engines.”

The Chevrolet Performance LT4 Shown Here

As noted higher up in the introduction, this engine was built by Aaron Kurt of Late Model Engines, an expert on the LT4.

This LT4 build is based on an original GM LT4 block that was precision bored to 4.070 inches and assembled with a lengthy list of top-shelf components. Inside you’ll find a Callies 5T0-31Q-CS.0 forged crankshaft with Texas Speed I-beam connecting rods, ARP 2000 bolts, and Diamond 2K forged pistons – fitted with Total Seal rings. The rotating assembly runs on Clevite H-Series main bearings and ACL rod bearings, secured by ARP main studs.

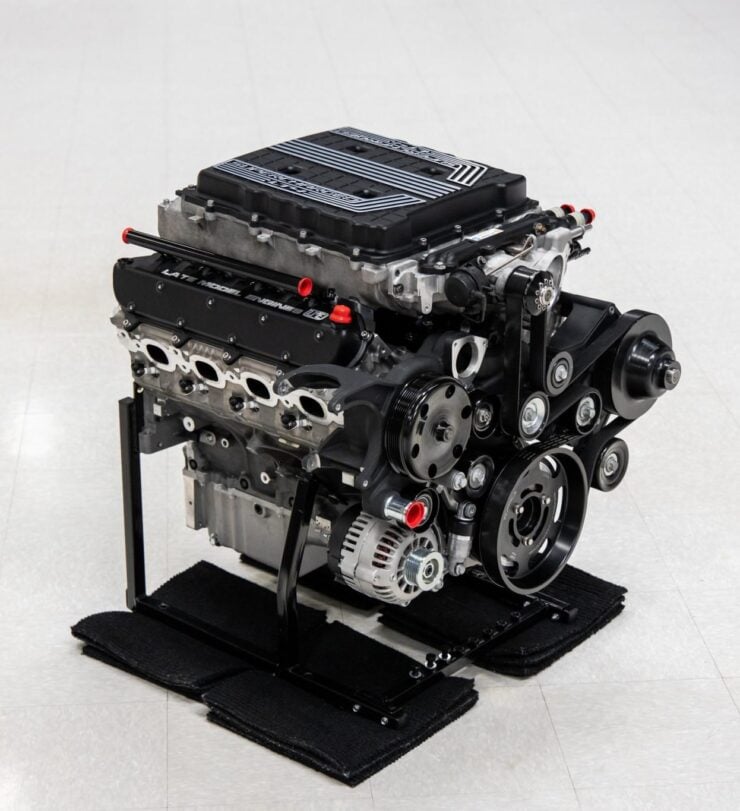

The camshaft is a custom-ground Cam Motion unit with 244/252 degrees of duration, .640/.630 inch lift, and a 116+4 LSA, working with Johnson 2116LSR tie bar lifters and Brian Tooley .660-lift valve springs. It also has an LME billet timing chain guide, a Cloyes timing chain, and an LME VVT delete billet timing cover finished in textured black.

Up top, a pair of GM LT4 cylinder heads ported by Late Model Engines are configured without direct injection provisions. They’re fitted with GM LT1 hollow-stem intake valves, R.E.V. stainless exhaust valves, LME titanium retainers, and upgraded rocker arms with Comp Cams trunnions.

Forced induction comes from a GM LT4 supercharger ported by LME and fitted with new bearings, oil, and a 103mm throttle body opening. It’s topped by an LT4 lid finished in chrome and black powdercoat, with boost supplied by a GripTec 2.30 inch upper pulley on a ZPE hub and a DSX 9.06 inch lower pulley. Fuel is delivered through DSX Ultra Low port injection plates and 1300cc injectors from Fuel Injector Connection.

Finishing touches include a Holley LT4 mid-height accessory drive system, an ICT billet fuel pump lifter block-off plate, and a six-quart LT swap oil pan. The result is a fully re-engineered LT4 built to handle significant boost pressure and high-RPM operation, producing 821 bhp and 797 lb ft of torque on 93 octane pump gas.

The engine is now being offered for sale out of Seekonk, Massachusetts with an engine stand, dynamometer chart, parts list, and specification sheets. If you’d like to read more about it or place a bid you can visit the listing here.

Images courtesy of Bring a Trailer