This is an Ardun-Ford 276 V8, it started out as a Ford Flathead V8 but it’s been highly modified now, including the fitment of Ardun overhead valve heads, that vastly improve breathing and performance.

Ford Flathead V8s were the original mainstay engine of the hot rodding world, offering V8 performance one a budget most could afford starting in 1932. Ardun heads took the engine one step further, and as such they become popular both for hot rod builds and drag racing set ups.

History Speedrun: Ardun Heads

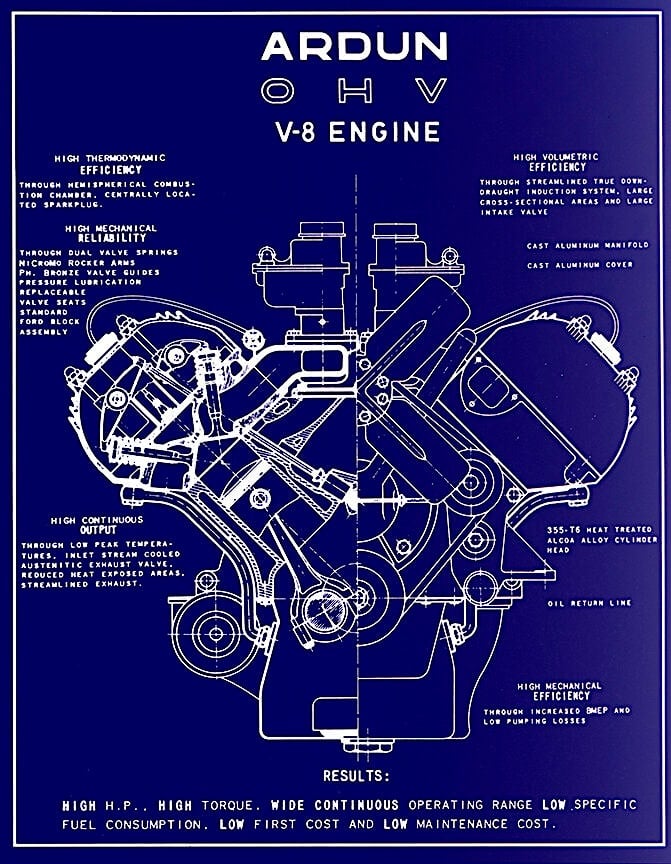

The Ardun overhead-valve conversion heads were among the most significant upgrades ever devised for Ford’s flathead V8. Developed in the late 1940s by brothers Zora and Yura Arkus-Duntov – Belgian-born engineers of Russian heritage based out of New York – the Ardun (a contraction of “Arkus-Duntov”) was designed to fix the flathead’s two biggest weaknesses – poor breathing and chronic overheating.

By 1947, the Duntov brothers had turned their engineering attention to Ford’s popular (but thermally challenged) V8. Their company, Ardun Mechanical Corporation, had built munitions and tooling during World War II, and after this they focused on designing automotive performance parts.

The Ford Flathead V8 was affordable and plentiful, but its side-valve design limited power and created hot spots around the exhaust ports. The Duntovs’ solution was to convert it into a hemispherical-chambered overhead-valve (OHV) engine. Each head was a complex aluminum casting with individual rocker assemblies and cross-pushrod actuation, placing the valves directly over the combustion chambers for better flow and cooler running.

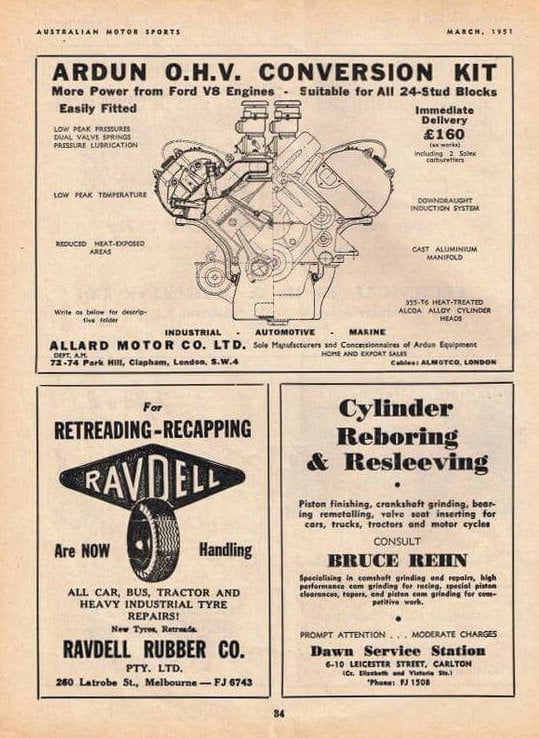

The conversion kit was released in the late 1940s, not long after WWII, it included two aluminum heads, valves, springs, rocker arms, pushrods, lifters, intake and exhaust manifolds, rocker covers, and port plates. It improved airflow, cooling, and reliability while completely transforming the engine’s character. A stock Ford 239 cubic inch flathead made about 100 bhp, but with Ardun heads output rose to roughly 150 bhp in street trim and up to 175 bhp in race tune.

Compression ratios varied depending on piston design rather than the heads themselves. The setup added about 60 lbs of weight and made the engine noticeably wider, but those were small prices to pay for the performance gains on offer.

By the early 1950s, Ardun heads had become a fixture in American performance culture. Hot Rod Magazine’s 1956 feature The Ardun: What Makes It Run? detailed its intricate geometry and valvetrain design, noting both its ingenuity and its practical challenges – issues like lifter galling and gasket sealing that accompanied early castings.

When Zora Arkus-Duntov later joined General Motors, he brought with him an understanding of high-performance engine design that would influence Chevrolet’s Corvette program – in later years he would be nicknamed the “godfather of the Corvette.”

Original production of the Ardun conversion was short-lived – about 200 to 250 pair-sets were completed – but the idea never died. Interest revived in the 1960s and 1970s, and by the mid-1990s, California-based engineer Don Orosco produced 30 accurate reproductions.

Today, Don Ferguson Enterprises manufactures new Ardun heads with updated materials, improved geometry, and CNC machining. These modern versions remain popular among vintage racers, Bonneville competitors, and traditional hot rodders seeking both authenticity and performance.

The Ardun-Ford 276 OHV V8 Crate Engine Shown Here

The crate engine you see here is a custom-built Ardun-Ford 276 V8 – assembled by National Street Rod Association co-founder and custom car builder Irvin “Cotton” Werksman.

The engine now has Ardun overhead-valve cylinder heads, a Howards Cams F371 camshaft and a polished Jim Inglese eight-stack induction system with four Weber IDF carburetors, velocity stacks, braided fuel lines, and a fuel-pressure gauge.

It’s been bored .125″ over for a total displacement of 276 cubic inches (4.52 liters). The Ardun cylinder heads have also been ported, and it’s fitted with a Mercury forged steel crankshaft and Jahns 9.5:1 pistons.

The engine is now being offered for sale out of West End, North Carolina on Bring a Trailer with a custom crate, an engine stand, spare parts, velocity stack caps, exhaust port block-offs, an Ardun/Arkus-Duntov-signature clock, and and a bill of sale.

If you’d like to read more about it or register to bid you can visit the listing here.

Images courtesy of Bring a Trailer