The Lotus Elan marked a turning point in the history of Colin Chapman’s Lotus Cars – it pioneered the trademark Lotus backbone chassis with a fiberglass body, and it marked a transformation from Lotus being thought of as a kit car maker to being a manufacturer of turn-key sports cars that offered impeccable handling.

Colin Chapman: Genius in a Modest Sports Car

Lotus Cars had very humble beginnings building trials cars based on the 1930’s vintage Austin 7 small sedan. As things progressed from the 1940’s through the 1950’s and into the 1960’s those trials and hillclimb cars – often sold as kit cars were skillfully morphed into the highly successful Lotus 7.

Alongside the development of the Lotus 7, Colin Chapman created a parallel series of dedicated racing cars with space frame chassis of his own design and in the mid-1950’s work was underway to create the first “proper sports car” which made its debut as the Lotus Elite at the Earls Court Motor Show in London in 1957.

The Elite would continue in production until 1963 by which time Colin Chapman and his engineers had analyzed what needed improving and set about creating a new model, of about the same size and concept, but much improved.

Colin Chapman had tended towards using space frame chassis for his cars and tried a load-bearing fiberglass monocoque for the Lotus Elite. But these were quite complex and expensive to produce, and the Lotus Elite was cause of considerable trouble because the technology surrounding fibreglass in automotive applications was at that time in its infancy.

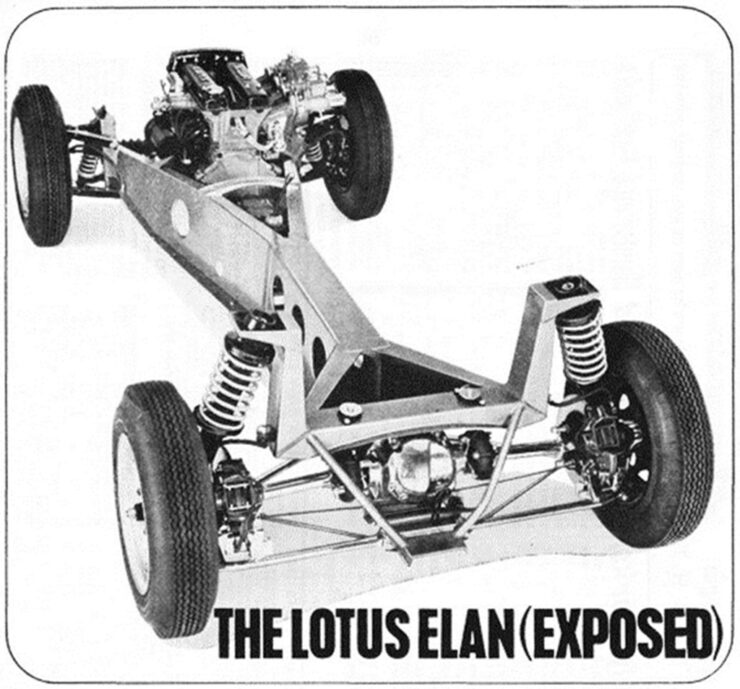

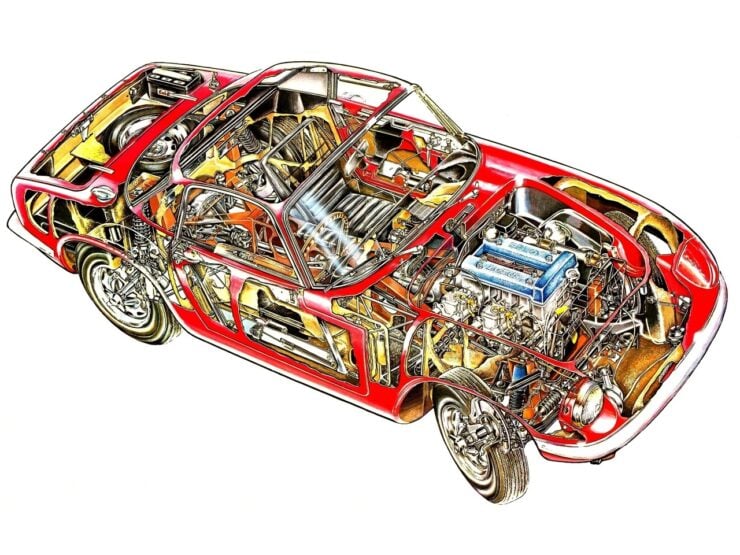

So instead Chapman’s design team went the way of the original Volkswagen and Porsche and their predecessors, and opted for a steel backbone chassis, a type of chassis pioneered by an associate of Ferdinand Porsche, Czechoslovakian engineer Hans Ledwinka. So well suited to Lotus’ cars was the backbone style chassis combined with a fibreglass body that it would become the foundation on which successive Lotus cars would be based including the mid-engine Europa and Esprit: the Elan was the model whose design pioneered this.

The backbone chassis created by the team at Lotus for their new sports car was much more advanced than those of Porsche and Ledwinka’s early efforts. Instead of being a tubular backbone Lotus chose to build a folded steel backbone that forked into an “X” shape to accommodate the engine, front and rear suspension, and the differential.

One of the reasons Colin Chapman and his team decided on the backbone chassis was because they wanted to build a car that would be superbly stiff when made in open top roadster form: and this they accomplished. Credit for the backbone chassis design goes to Ron Hickman, who was in charge of Lotus Developments. Colin Chapman’s original thinking was towards a roadster that exemplified his saying “Simplify, and then add lightness”.

It was to be ultra lightweight to the extent that it did not even feature opening doors: a car that would appeal to the sports car purists, and a car that would also act as a replacement for the Lotus 7.

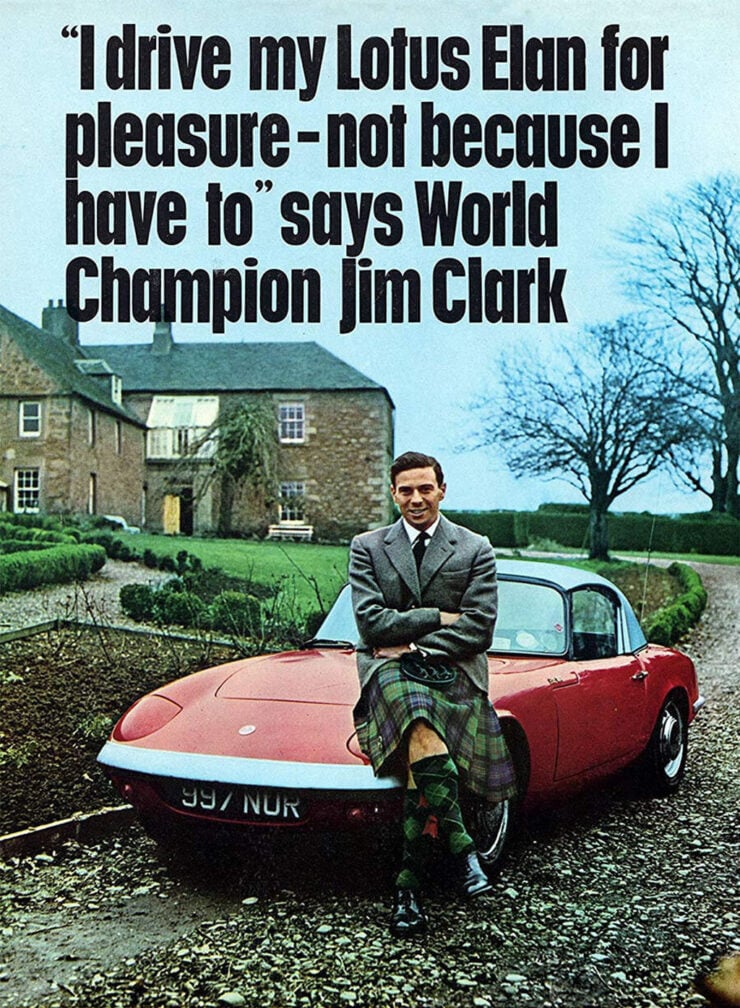

Ron Hickman’s idea was for a sports car that would occupy the market space between such production cars as the MGB and Triumph TR4, and the more expensive Jaguar E-type (XKE): a car that was affordable for most enthusiasts both to buy and to maintain, and a car they could maintain themselves. But also a a car that offered exciting performance and exemplary handling, arguably even better handling than any of its competitors be they less or more expensive.

A car that offered a driving experience second to none: and Lotus succeeded in creating exactly that: and not only that, but it helped establish Lotus as a credible sports car manufacturer, and set the company on the path that would lead it to the future Colin Chapman had envisioned for it – to become a maker of top class sports cars in the same league as Porsche and perhaps even Maserati.

The Elan made her debut at the London Earls Court Motor Show of October 1961.

The Anatomy of an Elan

The Elan was originally created so it could be offered both as a kit car, and as a fully assembled car: so it was made with owner assembly in mind and this helps to make it a good selection for someone who wants to be able to maintain the car, or completely disassemble it for restoration or improvements.

Its a bit of a grown-up “boys own” Meccano set. So if you’re into a bit of “DIY” (i.e. Dismantle It Yourself) followed by some “BIY” (Build It Yourself) then an Elan is potentially a good candidate on which to get your hands dirty.

As previously mentioned the foundation of the Elan is the folded steel backbone chassis to which was mounted the suspension and steering components, engine, gearbox, and differential etc. Then over that was fitted the glass fibre body with its interior fittings, doors, boot and bonnet lids etc. The body was attached to the chassis by sixteen bolts.

Lotus used industry available parts where possible to keep production costs down and ensure owners would be able to get parts for their cars. For example the Elan was fitted with a Triumph rack and pinion steering mechanism which was variously used in such cars as the Triumph GT6 and Herald. It proved superbly suited to the Elan and gave its steering legendary sensitivity.

The front suspension was a mix of Lotus lower wishbones combined with Triumph GT6 uprights, while at the rear was a Chapman strut independent suspension which utilized modified Ford Cortina front suspension components.

The Elan was given Girling disc brakes all around: Chapman had wanted to mount the rear discs inboard but this proved impossible due to the Rotaflex drive couplings being used.

Under the bonnet was installed a modified Ford four cylinder twin-cam engine mated to a Ford four speed gearbox. This engine was created based on the small Ford four cylinder sedan car engine in a cooperative effort between Colin Chapman and Walter Hayes at Ford.

The design work for the twin-cam cylinder head for this engine was done by Harry Mundy, who had previously worked at Coventry Climax. These engines were originally built by J.A. Prestwich (JAP) up until 1967 when Lotus took over their own production. (JAP were one of Britain’s most iconic engine makers and were the makers of the engines for the Brough Superior motorcycles of the 1930’s. The rear differential was also Ford, and modified to suit the Elan’s independent rear suspension.

The body of the Elan was not just styled, it was made to be aerodynamic both for performance and wind noise moderation. John Frayling worked on the body, interior and ergonomics to create a car that was comfortable, well ventilated, quiet, and which delivered a driving experience to delight the owner.

The task of preparing the Elan for production was given to ex Rolls-Royce engineer John Cope-Lewis. It would take a couple of years for the quality control of the new Elan to be brought up to the standard of excellence sought, so early cars were subject to quality control issues. During this period Lotus were transitioning from being a manufacturer of kit cars such as the Lotus 7 to becoming a maker of exotic sports cars and as a result quality control issues were to be expected.

The first cars were fitted with 1,500cc engines but the decision was taken early to upgrade to the 1,558cc version and in an interesting turn of events owners of those first twenty two cars were given the option to have their 1,500cc engines swapped to the 1,558cc version free of charge.

This was actually advantageous to Lotus as the 1,500cc engines were in short supply and in demand for racing. This means that few if any of the early S1 Elans that retained their 1,500cc engines.

Model History Summary

The Elan was produced in four series with the addition of the “Sprint” version of the two seater model. In addition to this a slightly larger Elan +2 was added to the range which was mechanically kept as similar as possible to the two seater model. This car provided an additional two compact seating positions suitable for children in the rear.

For a detailed description of the models and their features please have a look at the Lotus Elan Registry website.

Lotus Elan S1

The first model, known as the Type 26. Produced from 1962 this model began fitted with the 1,500cc version of the DOHC Ford/JAP engine as the Elan 1500 and was quickly supplanted by the Elan 1600 fitted with a 1,558cc version of the same engine. Only twenty two of the Elan 1500 were produced. The Elan 1600 began to be offered with an optional hard top.

The Elan 1500 had a “1500” badge on the boot and both it and the 1600 had lift up side windows and not roll up windows at that stage. Both featured round tail light assemblies.

Lotus Elan S2

Beginning in 1964 the Elan S2 replaced the Elan 1600, but was still known as a Type 26 by Lotus. Production of this model began with the same round tail light assemblies as the S1 cars but these were changed to oval tail light assemblies as production progressed.

The S2 cars were still being fitted with the simple lift up side windows.

There was also a Type 26R racing version made with a lightweight body and generally fitted with fixed headlights, Lotus designed peg drive wheels and flared fenders.

Lotus Elan S3

Beginning 1965 a Fixed Head Coupe version of the Elan entered production. This model was designated the Type 36. Early versions did not have ventilators on the “B” pillar while later “Airflow” versions do.

The S3 Drop Head Coupe version was designated the Type 45 and featured electric roll up windows with fixed frames.

S3 did away with the rather complex bonnet/hood mountings of the earlier cars and replaced them with a simpler system.

Lotus Elan S4

The S4 was also made in Fixed Head and Drop Head Coupe styles. The S4 featured square tail light assemblies and square profile wheel-arches along with electric windows.

The S4 was also offered as an “SE” version with two tone paint as standard (although a purchaser could opt for a single colour if desired). The SE also has an “SE” badge and stainless steel side trims, along with wing mounted flasher repeater lights.

Lotus Elan +2

Introduced in 1967 the Elan +2 was made in a few variants. Designated the Type 50 +2 the first basic model was followed by the Type 50 +2 Federal made for the North American market: these being left hand drive and fitted with flush interior door handles and a remote boot/trunk release.

The Type 50 +2 2S and its North American market LHD sibling the Type 50 +2 2S Federal featured an upgraded interior with improved instrumentation and seats, and came fitted with fog lights/driving lights set below the front bumper.

The Type 50 +2 130 featured a “Big Valve” engine and its sibling was the Type 50 +2 130/5 was fitted with a five speed gearbox in place of the original Ford four speed.

Specifications and Variants

Chassis and Body:

Backbone chassis made of folded mild steel. Separate fibreglass body which was lowered onto the rolling chassis during production and attached using sixteen bolts.

Dimensions:

Two seater versions

Length: 145″ (3,683 mm)

Width: 56″ (1,422 mm)

Height: 45″ (1,156 mm)

Wheelbase: 84″ (2,134 mm)

Kerb Weight: 1,500lb (680kg)

Elan +2 Versions:

Length: 169″ (4,293 mm)

Width: 66″ (1,676 mm)

Height: 47″ (1,194 mm)

Wheelbase: 96″ (2,438 mm)

Kerb Weight: 1,960 lb (889 kg)

Fuel Tank Capacity:

S1, S2 and S3 cars: 10 gallons (Imperial). 12 US gallons.

S4 cars: 9.5 gallons (Imperial). 11.4 US gallons.

Elan +2 cars: 13 gallons (Imperial). 15.6 US gallons.

Suspension, Steering and Brakes:

Brakes: Discs front and rear. Front: Girling 9.5″. Rear Girling 10″ rear.

For SE, Spirint and Elan +2 versions brakes are servo assisted with Girling 10″ at the front and Girling 10″ at the rear,

Wheels and Tyres: 13″x4.5″ standard pressed steel 4 bolt with 5.20×13″ cross-ply tyres. Optional 145×13″ radial Dunlop SP41. For SE and Sprint 4.5J pressed steel with centre lock knock-on 5 peg drive with 165×13″ Dunlop SP Sport, Firestone F100 or Goodyear G800. For Elan +2 5.5J pressed steel with centre lock knock-on with 5 peg drive. +2 130 and +2 130/5 cars fitted with optional alloy wheels. Tyres for the +2 were 165×13″ Dunlop SP Sport, Firestone F100 or Goodyear G800.

Engines: Each based on the Ford Kent pre-crossflow modified with an alloy DOHC cylinder head designed by Harry Mundy. Camshafts chain driven.

S1 Elan 1500: 1,498cc Lotus Twin Cam

S1 and S2 Elan 1600: 1,558cc Lotus Twin Cam

- Standard engine: Power 105bhp @ 5,500rpm and torque of 108lb/ft @ 4,000rpm

- SE engine : Power 108bhp @6,000rpm and torque of 108lb/ft @4,000rpm

S3, S4, and Elan +2

- Standard engine: Power 90bhp @ 5,500 rpm and torque of 108lb/ft @ 4,000rpm

- SE engine: Power 93bhp @ 6,000rpm and torque of 108lb/ft @ 4,000rpm

- Sprint engine “Big Valve”: Power 126bhp @ 6,500rpm and torque of 113lb/ft @ 5,500rpm

- Sprint engine with emissions controls: Power 113bhp @ 6,500rpm and torque of 104lb/ft @ 5,000rpm

Transmissions:

- For most cars Ford four speed manual gearbox, with Ford differential modified to fit the independent rear suspension.

- For late model cars Lotus built gearbox using Austin Maxi/Allegro five speed manual transmission components.

Performance:

The Elan was made in a variety of configurations with differences in engine power and final drive ratios. For the original S1 and S2 cars standing to 60mph figures were typically about nine seconds and top speed was around 110mph. The S3 SE and S4 SE did standing to 60mph in about seven and a half to eight seconds with top speeds around 120mph. The Elan Sprint was capable of delivering standing to 60mph in 6.6 seconds and a top speed of 123mph.

Buying a Lotus Elan

The Elan was originally offered as either a complete car or as a kit for the owner to assemble themselves. The car was intended to be owner modified as desired and there are pluses and there are cautions associated with this. The value of the car will be strongly influenced by its originality and more scarce models tend to be valued more highly than the more common ones.

This means that a vendor may have “created” their own “scarce” model to sell at a handsome profit. So a check on the car’s history is needed and that means assessing the documentation that comes with it along with the chassis number. That being said bear in mind that an Elan’s original chassis is likely to have accumulated rust damage and will quite probably have been replaced at some point – hopefully with a galvanized new one.

The chassis needs to be checked for cracking, especially around suspension and final drive mounting points, and in the “Y” sections front and rear. The chassis rear suspension turrets and tubes need to be assessed, as do the mounts for the final drive torque rods.

If you intend to purchase a car that is known to be modified, such as a custom modified drop head coupe Elan +2 for example, go into that purchase with your eyes open as it’s value will be rather less than an original car. The Two +2 was not originally manufactured as a drop head coupe.

Despite the Elan having a fibreglass body it was originally built on a folded mild steel chassis and British cars of that period were not known for the efficacy of their rust proofing.

So an Elan is likely to either have had the original chassis replaced (preferably with a galvanized one) or to have had rust repair work done. This is your first port of call in assessing a car you might purchase. There is also steel stiffening around the door openings. Replacement chassis are available from Lotus Cars and Spydercars.

The fibreglass bodywork needs to be assessed for deterioration and repair work. Fibreglass may not rust but it does deteriorate over time so look for signs of cracking and crazing. Similarly look for evidence of repair work and evaluate the quality of any repair work you find. For Elan +2 cars pay special attention to the sills.

The electrics of an Elan are going to be in need of full assessment. Because of the fibreglass body many electrical fittings need to be double wired – i.e. have to be wired back to the chassis for earth – and this complicates the wiring, adding more points for potential problems.

The engine of the Elan is based on a good basic Ford foundation and its secret to performance lies in the Harry Mundy designed alloy DOHC cylinder head. The design of this cylinder head comes in a few variations depending on whether the car was destined for the domestic UK market or if it was a North American specification car.

The North American specification cars were fitted with Stromberg carburettors as a part of their emissions controls and these don’t lend themselves to fitting alternative carburettors such as Webers for example.

Car’s with alloy cylinder heads absolutely require that the correct anti-corrosive coolant is used to prevent corrosion damage. Do the usual checks for signs of oil leakage into the cooling system and coolant leakage into the oil.

Oil pressure should be about 20psi on idle and 40psi while driving. The cars have an electric cooling fan that is thermostat controlled. The water pump is a know weakness. The original water pump was located such that removing it required the cylinder head to be removed. Some owners will have converted that so that the pump is able to be removed without cylinder head removal: a removable pump will have bolts visible around it.

The rear independent suspension required rubber doughnuts when the Elan was first made and so these required periodic replacement. Nowadays these rubber doughnuts have acquired a reputation for being of variable quality and it is common for owners to replace them with CV joints.

Conclusion

A Lotus Elan is one of the great cars to bear the Lotus marque, and it is without doubt the model that marked the shift from Lotus being a maker of kit cars to them becoming a credible manufacturer of high performance sports cars. It is a refined British sports car that was technologically advanced and yet affordable.

The steering and suspension are without doubt second to none, and its aerodynamics excellent. On top of that it is a pretty car in a restrained and unpretentious way. In short it is the epitome of the best of Britishness – intelligent and imaginative design wrapped in a restrained and elegant package.

Picture Credits: Bonhams, Lotus Cars, RM Sotheby’s.